Safe like a Robot. Drives like a Human.

Jaguar Land Rover advances in autonomous driving, focusing on safety & luxury. They utilize data analytics & partnerships, like with NI & NVIDIA, for efficient testing and innovation in driver assistance.

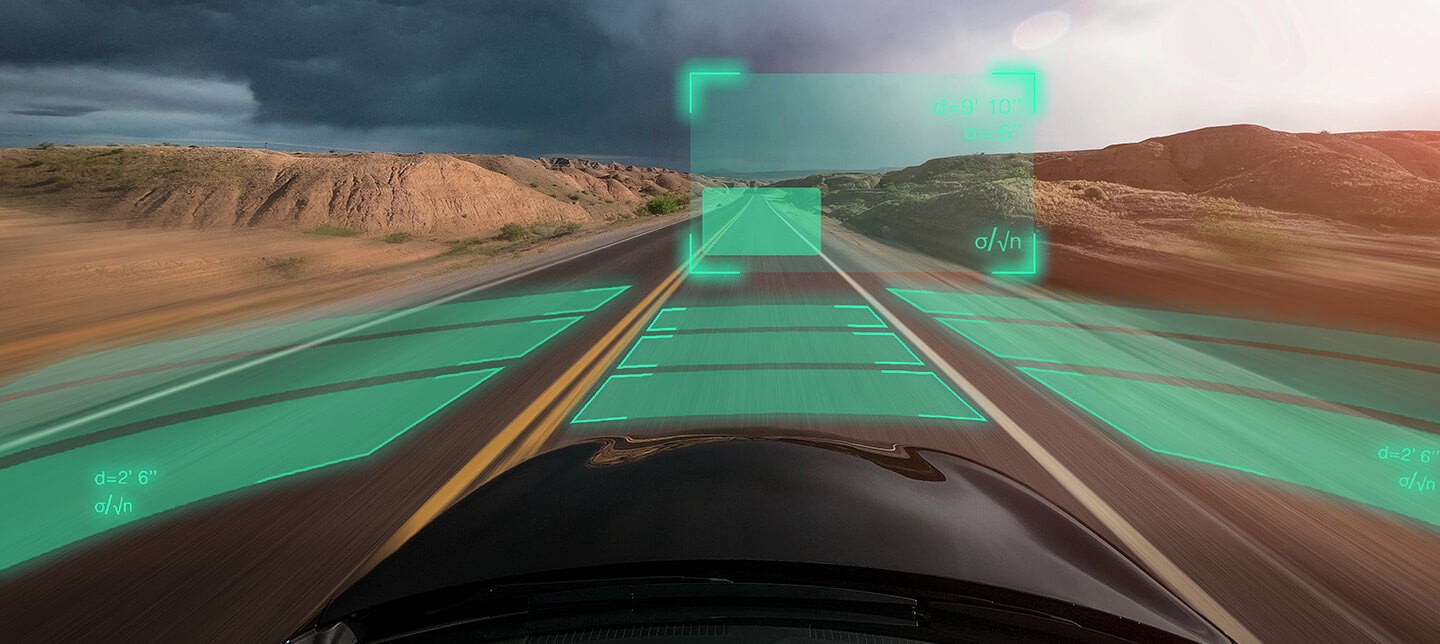

Autonomous vehicles need to be able to visualize, understand, and react to the world around them to operate safely. The first step is accomplished by a variety of sensors and cameras utilizing radar, visible light, ultrasonic, and LiDAR to collect data that’s sent to onboard computers for processing. LiDAR has emerged as a particularly important technology for automakers interested in pushing the current limits towards autonomous driving.

LiDAR stands for Light Detection and Ranging. Simplified, LiDAR systems have three major components: a laser that emits light pulses, a detector to measure the time it takes to receive the reflected light pulse signals, and a processor that calculates the distances to and locations of surrounding objects based on that data. This processing creates a point cloud, a detailed three-dimensional picture of the world around the vehicle that includes people, animals, street signs, road markings, obstacles, and other cars and trucks. That point cloud allows the vehicle to visualize the scene in detail. The technology is sometimes referred to as time-of-flight (ToF) LiDAR because it measures the time between a laser beam being sent out and when the reflection returns to paint an electronic picture.

Laser pulses are emitted in rapid succession for real-time coverage—think tens of thousands to hundreds of thousands of pulses per second. The type of information collected is critical for the safe operation of autonomous vehicles, which is why the development and testing of LiDAR technology has become important to auto manufacturers pursuing the highest levels of drive automation up to self-driving cars.

Let’s discuss the LiDAR technologies in scope for self-driving cars. On the highest level LiDARs are differentiated as:

Light pulses are emitted from a rotating assembly (e. g. on the roof), enabling complete coverage of the surrounding environment. While mechanical LiDAR has a 360-degree field-of-view (FoV), the device tends to be bulky and needs to sit on top of the vehicle. These constraints can make it impractical for commercial use outside of mapping or other specialized technological applications.

The laser emitter and detector sit on a single microchip. A beam of light is emitted/received by the sensor without the use of moving parts. The tradeoff, however, is that you need multiple sensors to provide full coverage around a vehicle (limited FoV). The relative simplicity of this technology makes it the preferred option for many automakers.

Here are some different approaches to solid-state LiDAR on autonomous vehicles:

The technologies around LiDAR are continuously evolving. Combinations, like adding mechanical components like mirrors and/or prisms to as solid-state based design, are quite common today forming hybrid LiDAR systems.

The purpose of automotive LiDAR is to use light to build a point cloud and help the car “perceive” its surroundings so onboard processors can safely navigate the environment without input from a human driver.

LiDAR is currently used in many Advanced Driver Assistance Systems (ADAS), like adaptive cruise control and lane keeping. While it’s not the only option to help autonomous vehicles visualize their surroundings, LiDAR has the following advantages:

The use of LiDAR on vehicles isn’t without its challenges, like system complexity leading to higher cost. LiDAR suppliers are hard at work to push the cost per unit down below the $1,000 and further on towards the $500 barrier – but still, at these price levels LiDARs remain more expensive compared to radars (below $100) and cameras (below $25). Additionally, the chips needed to build LiDARs can sometimes face supply chain challenges, as manufacturers add more of these to their vehicles.

Weather can also create issues, as precipitation like rain and snow can reflect or absorb LiDAR signals. This absorption reduces the LiDAR range and impacts performance in inclement weather.

While there are no fully autonomous vehicles on the market today, LiDAR is likely to be along for the ride when they debut.

While both technologies can detect objects, LiDAR and radar have major differences. LiDAR emits laser beams while radar uses radio waves. LiDAR’s advantages include higher resolution return signals for more detailed maps, while radar has a greater range. LiDAR provides a 3D maps (point cloud) while radars typically just operate in 2D (excluding developments around 4D imaging radar). Radar sensors are also currently more affordable than LiDAR units.

The genius lays in the “AND”. LiDAR and radar can work in concert for ADAS and autonomous driving features and complement each other. This type of collaboration is referred to as “sensor fusion” and takes advantage of the strengths of each technology.

Figure 1: Comparison of LiDAR and Radar Sensors

NI hardware and software support LiDAR testing for original equipment manufacturers (OEMs), suppliers, and researchers. Sensors can be tested at the individual level and as part of an integrated system. The ADAS HIL Sensor Fusion Test Workbench from NI partner Konrad Technologies allows engineers to connect and test a variety of sensors to simulate real-world operation in a vehicle.

With the proliferation of sensors needed to make autonomous driving a reality, many automakers’ test needs overlap those of semiconductor manufacturers. NI’s expertise and solutions span both sectors and can help companies shepherd sensor technologies through development and test and into production.