Maximizing Data Movement and Signal Processing with the NI PXI High-Speed Serial Module

Overview

Applications such as radar and imaging, wideband spectrum monitoring, radar target generation, channel emulation, and real-time spectrum analysis face significant challenges in streaming and processing high-volume, high-speed data without causing bottlenecks. For example, when acquiring large amounts of RF data from multiple instruments, data will likely need to be aggregated and undergo signal processing before it can be stored on a server for additional offline analysis. In addition to the high-volume data acquired by test instruments, some applications will also need closed-loop or semi-closed-loop deterministic signal processing for system prototyping and validation. These systems are designed to operate in real-time to reflect real-world scenarios. This can be especially difficult for wideband signals because they are sampled at extremely high rates and therefore require a powerful FPGA and low latency to reflect these real-world scenarios. This is crucial in environments where timing and precision are necessary to create reliable, controlled environments and reduce risk for these types of applications.

To address these challenges, NI provides a modular approach to test with the PXI system and high-performance software tools that can scale and adapt to evolving DUT needs. In this paper, learn more about NI’s high-speed serial and coprocessor PXI modules that are designed to address these challenges head on.

Contents

- High Performance FPGA Modules

- Aggregating and Processing High-Speed, High-Volume Data

- Application Example: Record and Playback for RF Data

- Hardware in the Loop with Real-Time Signal Processing

- Application Example: Radar Target Generation

- Software

- Additional Applications

- Next Steps

High Performance FPGA Modules

These PXI High-Speed Serial and coprocessor modules were designed for engineers who need high-performance FPGA coprocessing capabilities to achieve high volume data movement and inline real-time signal processing. They consist of open FPGAs that can be programmed using LabVIEW FPGA or VHDL. These instruments take advantage of multigigabit transceivers (MGTs) to support line rates up to 28.2 Gbps and up to 48 TX and RX lanes. As part of the PXI platform, they benefit from PXI clocking, triggering, and high-speed data movement capabilities, including streaming to and from disk, as well as peer-to-peer (P2P) streaming at rates up to 7 GB/s.

Table 1. High Speed Serial and Coprocessor Modules

1 Two-slot module

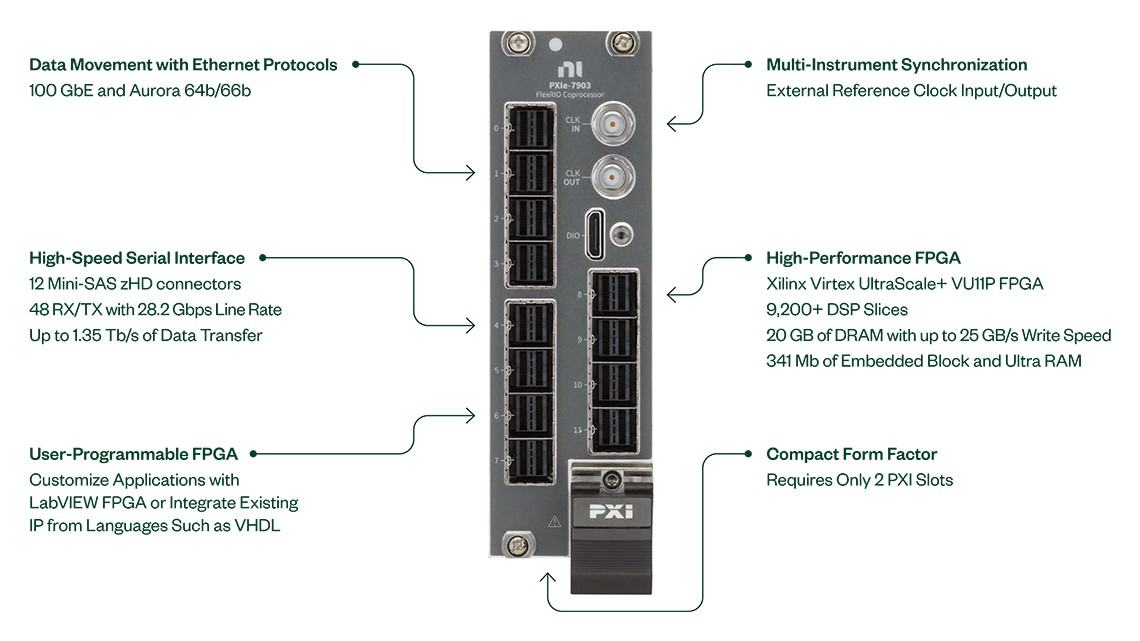

Applications such as the ones mentioned previously need powerful hardware and software in order to meet their testing requirements. The PXIe-7903 was built to maximize data movement and computational power. The PXIe-7903, taking two slots on a PXI Chassis, features 12 Mini-SAS zHD (Molex iPass+ zHD) connectors. Each connector includes four AC-coupled, differential TX and RX channels for a total of 48 channels supporting line rates up to 28.2 Gbps. The PXIe-7903 houses a user-programmable Virtex™ UltraScale+™ VU11P FPGA, enabling inline signal processing for multiple high-bandwidth instruments.

Figure 1. Detailed Diagram of PXIe-7903

The PXIe-7903 comes with protocol support for 100 GbE and Aurora 64b/66b including shipping examples in LabVIEW FPGA to help users get started. The VU11P has nine hardened media access controllers (CMACs) for 100GbE, which reduces FPGA fabric resource consumption, simplifies timing closure, and reduces power consumption. The VU11P also includes hard Reed-Solomon forward error correction (RS-FEC), which can detect and correct bit errors.

The Aurora protocol provides a lightweight, low-latency, small-footprint protocol designed for serial point-to-point interfaces. Primarily designed for high-bandwidth data movement, Aurora provides flow control, flexible framing, and options for simplex or full-duplex channels. Aurora 64b/66b is a point-to-point protocol developed by Xilinx. Aurora includes CRC for error correction but unlike 100 GbE, it does not include forward error correction. Learn more about high-speed serial instruments and protocol support in An Introduction to NI High-Speed Serial Instruments.

The PXIe-7903 is well suited for the following applications:

- Real-time spectrum analysis

- Radar target generation

- Comms algorithm prototyping

- System under test (SUT) emulation

- RF channel emulation

- Digital beamforming

Aggregating and Processing High-Speed, High-Volume Data

Challenges arise when there are multiple RF instruments that must offload data to a servers for offline processing, visualization, and storage. Wideband RF instruments, such as the PXI Vector Signal Transceiver (VST), can generate and receive greater than 1 GHz of instantaneous bandwidth, resulting in multiple GB/s of I/Q data to process and store. Not only does this amount of data create a signal processing challenge, but data movement interfaces can impose a bottleneck when dealing with such high data rates.

High-speed serial instruments alleviate this bottleneck by using multiple lanes of multigigabit transceivers (MGTs) to stream data into a powerful FPGA for processing, enabling the aggregation RF data from multiple instruments.

In these applications, high-speed serial modules can perform the following functions:

- Simultaneously aggregate data from multiple RF instruments

- Reach up to 20 times the throughput of the PXI backplane

- Record and playback data from RF instruments to servers at high speeds

- Communicate through different protocols such as 100 GbE and Aurora

Application Example: Record and Playback for RF Data

Wideband, multichannel RF data recording applications require you to aggregate and process large amounts of data simultaneously. For example, you may have a PXI VST that is acquiring synchronized RF data from multiple antennas. That data will need to be aggregated, processed, and offloaded to servers for offline analysis. You also may need to play back that data to test the response of the system under test.

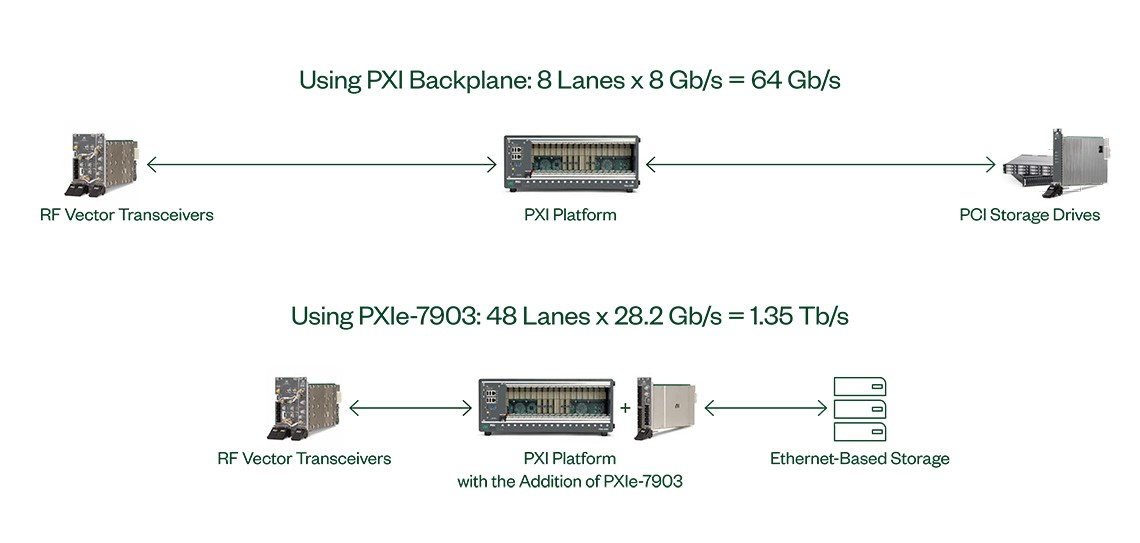

Traditionally, record and playback solutions for PXI systems would include an RF instrument, PXI chassis, and a storage device. As data steaming rates have increased, the streaming rates of the PXI backplane can become a bottleneck.

By using high-speed serial modules like the PXIe-7903, you can bypass the PXI backplane for up to 20 times the throughput. The PXI backplane consists of eight lanes that stream at 8 Gb/s for a total throughput of 64 Gb/s. Alternatively, the PXIe-7903 has 48 lanes that stream at 28.2 Gb/s. This combination results in a total throughput of 1.35 Tb/s.

Figure 2. Comparison of Data Streaming Rates with and without the PXIe-7903

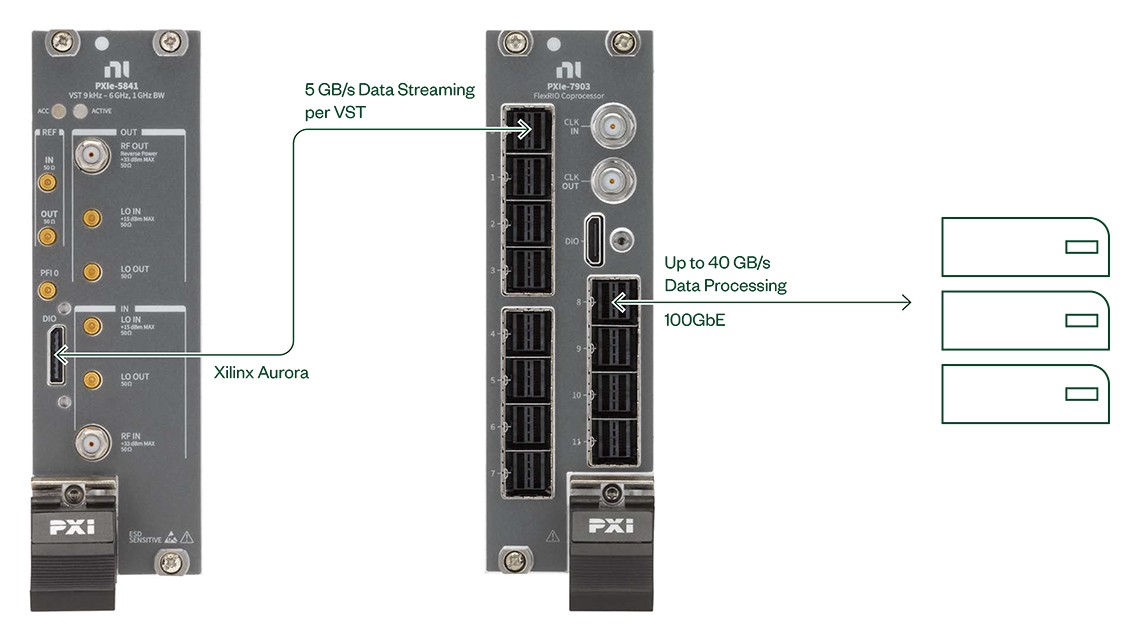

If you were to use the PXIe-5841 VST in a record and playback application, the VST samples at 1.25 GS/s provide 1 GHz of bandwidth. Each VST can stream 5 GB/s to the PXIe-7903 via an Aurora 64b/66b interface. Aggregating the data throughput across all eight VSTs results in a requirement of 40 GB/s of data processing, which the PXIe-7903 can aggregate and process simultaneously. You can then offload the I/Q data streamed from the VSTs to a server for analysis and storage.

Figure 3. PXIe-7903 can aggregate data from up to eight instruments, convert data from Aurora to 100 GbE, and stream to servers.

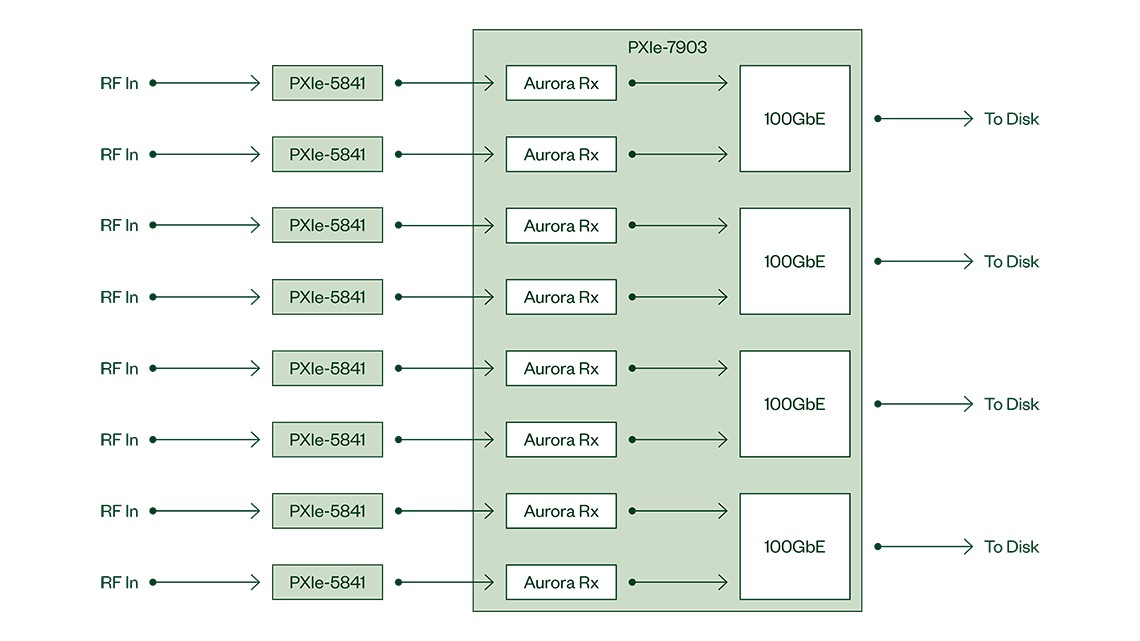

For example, if there were eight NI PXIe-5841 VSTs acquiring synchronized RF data, the I/Q data acquired on each PXIe-5841 will be written to a four-lane Aurora 64b/66b interface and streamed to the PXIe-7903. The PXIe-7903 multiplexes the I/Q data from a pair of four-lane Aurora interfaces into a single 100GbE UDP packet, for a total of four 100GbE interfaces to output data to disk. In this example, no inline processing is performed, which leaves up to 90% of the FPGA unused and available.

Figure 4. PXIe-7903 Processing RF Data from Aurora 64b/66b Interface to 100 GbE

By using high-speed serial modules, you can massively increase the data movement of your PXI system for applications that need to aggregate large amounts of data at high speeds.

Hardware in the Loop with Real-Time Signal Processing

Real-time signal processing has emerged as a critical component for applications such as radar and imaging. These applications typically include the simulation of specific testing conditions to evaluate the fidelity of their system under test. The importance of high-resolution RF data cannot be overstated, as it is vital for accurate target detection, tracking, and imaging.

To achieve this accuracy, these systems require real-time deterministic hardware, efficient algorithms, and a processing architecture that can handle the large amount of data generated. Real-time sustained data steaming enables the ability to change parameters and waveforms on the fly to visualize signal characteristics during operation to simulate real-world applications.

A key component in this process is the use of a user-programmable FPGA. This FPGA is necessary for real-time processing and implementing custom IP that is needed for creating these realistic testing scenarios. The combination of these elements provides a comprehensive solution for simulating real-world conditions in a controlled environment, to improve accuracy, reliability, and reduce risk.

In these applications, high-speed serial modules offer the following benefits:

- Ability to add custom functionality through user-programmable FPGA

- Real-time sustained data steaming

- Fidelity for realistic testing scenarios such as inline measurements, waveform replay, and augmented signal processing

Application Example: Radar Target Generation

Modern radars require extensive testing—from the component-level to full system-level—throughout the development cycle of the system. Radar target generators utilize RF I/O alongside processing technologies to create synthetic targets that allow radar system performance to be assessed for validation and functional test.

NI offers Radar Target Generation Software that allows VSTs to act as real-time, closed-loop radar target generators. The software allows four simultaneous in-beam targets per channel, with configurable time delay, frequency offset, and amplitude gain. Adding a high-speed serial instrument for coprocessing in this system allows custom IP to be integrated for parametric test and pulse analysis or for inline processing to inject realistic testing scenarios into the radar system under test.

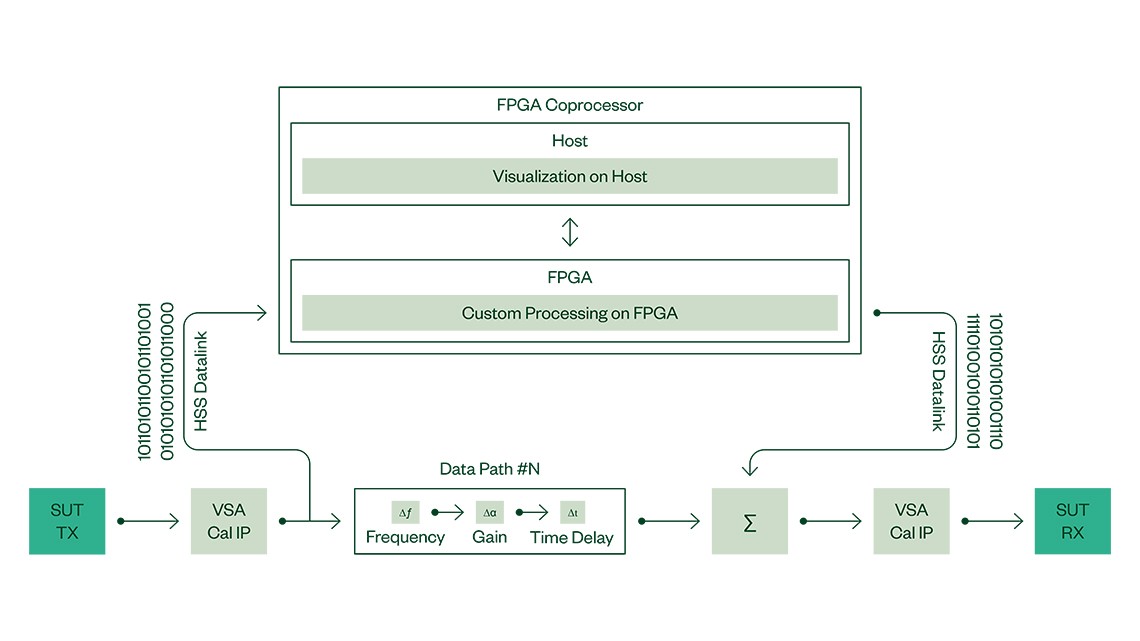

Figure 5 shows how radar pulses from the SUT are acquired by the VST and then branched off to the coprocessor using a high-speed serial link. Within the VST, synthetic targets are added to the signal. Within the coprocessor, the signal undergoes custom processing for inline measurements or for augmenting the echoes sent back to the SUT. This process allows the addition of effects caused by weather, clutter, jamming, or other scenarios.

Figure 5. Utilizing the FPGA on High-Speed Serial Instruments for Custom Applications

The high channel count and FPGA coprocessing power of high-speed serial devices offers the ability to perform extensive testing on radar systems to create realistic, reliable, controlled environments and to reduce risk and meet strict testing requirements.

Software

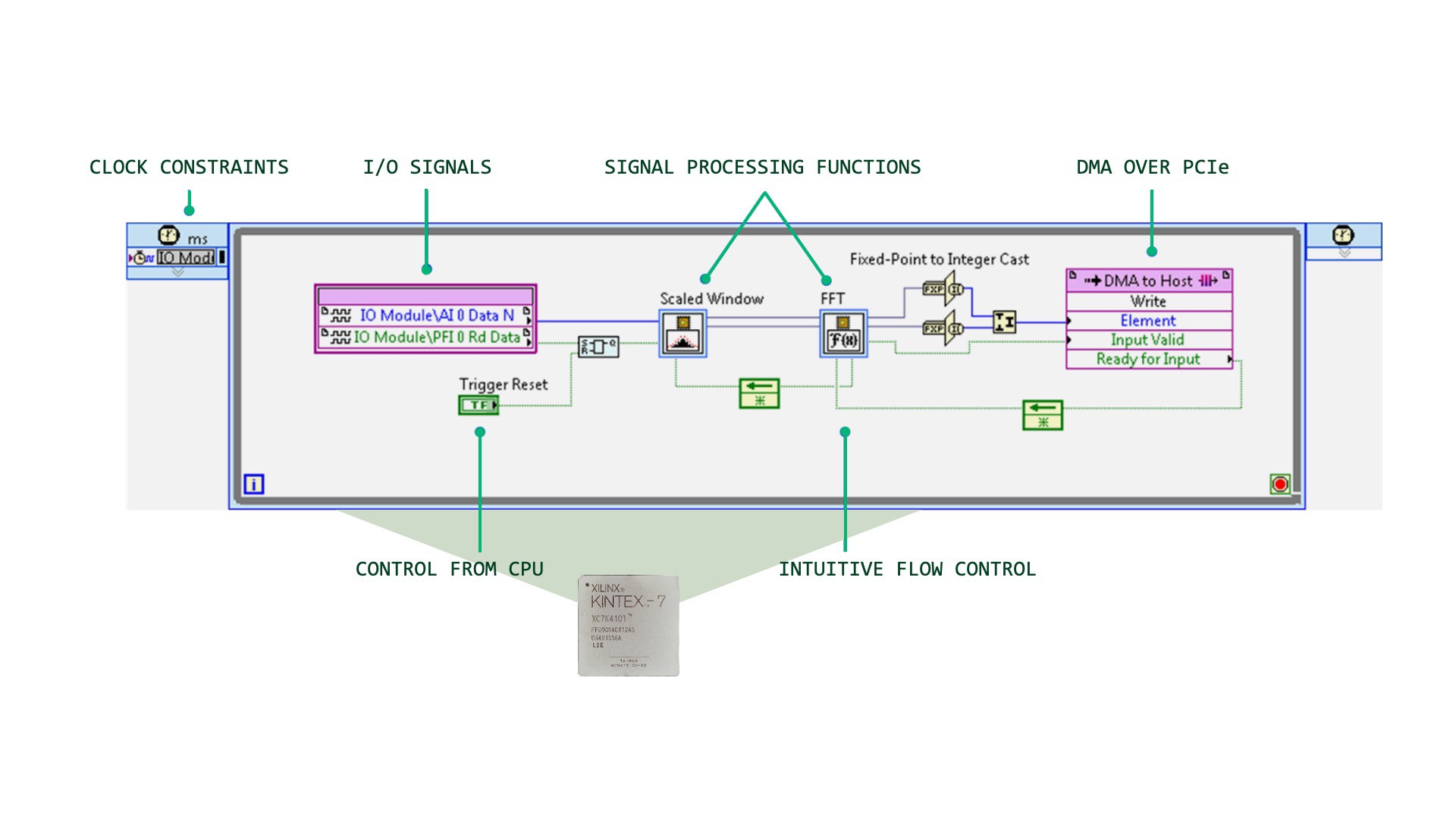

LabVIEW FPGA allows engineers and scientists to program FPGAs using graphical programming. LabVIEW FPGA is a powerful tool for designing and implementing custom hardware circuits that can provide high-speed and low-latency processing for a wide range of applications, including industrial automation, robotics, aerospace, and scientific research. With LabVIEW FPGA, you can design custom hardware circuits that run in real time, so you can implement high-speed, low-latency, and deterministic control and signal processing systems. LabVIEW FPGA helps to provide a workflow and tool for system integrators and test engineers to quickly instantiate complex IP/DSP on NI hardware.

Figure 6. LabVIEW FPGA provides a graphical programming approach that simplifies the task of interfacing to I/O and processing data, greatly improving design productivity and reducing time to market.

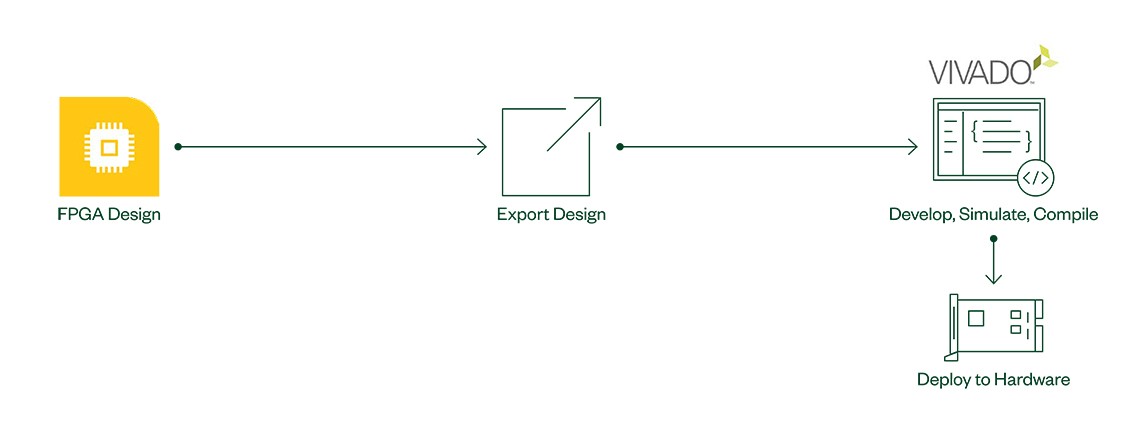

For programming with VHDL, experienced digital engineers can use the Vivado Project Export feature included with LabVIEW FPGA 2017 and later to develop, simulate, and compile hardware with Vivado. This method may be preferred for engineers who need lower-level control, optimization, and workflows. You can export all the necessary hardware files for a design to a Vivado project that is preconfigured for your specific deployment target. Any LabVIEW signal processing IP used in the LabVIEW design will be included in the export; however, all NI IP is encrypted. You can use Vivado Project Export on all high-speed serial devices with Kintex 7 or newer FPGAs.

In the software section of An Introduction to NI High-Speed Serial Instruments, you can find more information on programming with high-speed serial instruments.

Figure 7. For experienced digital engineers, the Vivado Project Export feature allows for exporting all necessary hardware design files to a Vivado project for development, simulation, and compilation.

Additional Applications

The PXI High-Speed Serial Instrument is also a key component in the following solutions for aerospace, defense, and semiconductor applications:

| Feature | PXIe-6594 | PXIe-7915 | PXIe-79031 |

| MGT Channels | 8 TX/RX | 4 RX/TX | 48 RX/TX |

| Aux DIO | 8 GPIO | 8 GPIO | 8 GPIO |

| Maximum Serial Data Rate (per channel) | 28.2 Gb/s | 16.4 Gb/s | 28.2 Gb/s |

| FPGA | Kintex™ UltraScale+ KU15P | Kintex UltraScale KU060 | Virtex™ UltraScale+ VU11P |

| Dynamic RAM | 8 GB | 4 GB | 20 GB |

| Block RAM | 34.6 Mb | 38 Mb | 341 Mb |

| DSP Slices | 1968 | 2760 | 9216 |

| PXI Backplane Link | PCIe Gen3 x8 | PCIe Gen3 x8 | PCIe Gen3 x8 |

| Connector | QSFP28 | Nano-Pitch I/O™ | Mini-SAS zHD |