Data Acquisition (DAQ)

Create DAQ systems with NI devices, sensors, and software like LabVIEW and FlexLogger™.

Turning Real-World Data into Insights

Every data acquisition task has its own set of requirements. To help meet your unique needs, NI products range from plug-and-play DAQ devices for fixed and repeatable measurements, to scalable and flexible modular DAQ systems. Our versatile driver is extended by NI data acquisition-specific software and supports third-party programming languages.

Systems

DAQ System Options

NI offers PC-based systems with plug-and-play DAQ devices with fixed functionality or configurable systems that let you mix and match hardware.

-

CompactDAQ

CompactDAQ

This portable, flexible approach is ideal for applications with a wide mix of measurement types, where scalability and flexibility are important. Hardware ruggedness makes it a great fit for high-channel-count distributed applications in the field.

Learn more -

CompactRIO

CompactRIO

Take advantage of real-time data processing capabilities, sensor-specific conditioned I/O, and a closely integrated software toolchain for long-running, industrial data acquisition applications.

Learn more -

PXI

PXI

Use this modular approach for high-channel-count data acquisition and sensor measurement applications. Systems range from tens to hundreds of channels, mixing and matching measurement functionality and output capabilities.

Learn more

CompactDAQ

This portable, flexible approach is ideal for applications with a wide mix of measurement types, where scalability and flexibility are important. Hardware ruggedness makes it a great fit for high-channel-count distributed applications in the field.

Learn more

CompactRIO

Take advantage of real-time data processing capabilities, sensor-specific conditioned I/O, and a closely integrated software toolchain for long-running, industrial data acquisition applications.

Learn more

PXI

Use this modular approach for high-channel-count data acquisition and sensor measurement applications. Systems range from tens to hundreds of channels, mixing and matching measurement functionality and output capabilities.

Learn moreDevices

Find the Right DAQ Hardware

NI’s DAQ devices are divided into categories to help you easily find options that meet your needs. Select by measurement type, such as temperature or strain, or common form factors, including USB.

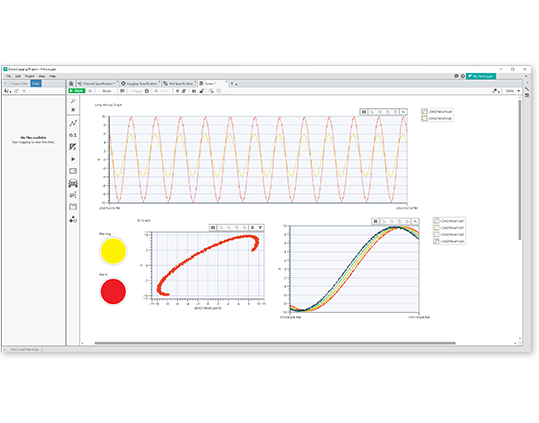

Accelerate Your DAQ Setup with Free FlexLogger Lite

Start your data acquisition with free FlexLogger Lite, included with supported NI hardware. Configure channels and log data effortlessly with no programming required. Adapt to project changes effortlessly and upgrade anytime to the full-featured FlexLogger for more complex tasks such as basic automation, triggers, and alarms.

Selecting DAQ Hardware

Identifying the right DAQ system or device for your project requires considering many factors. Here are some helpful resources to guide you toward an approach that delivers the data you need to make business decisions.

Choosing the Right Hardware

Choosing between DAQ Systems

Building a Measurement System

The software and hardware environment need for fast, convenient, and stable system development is indispensable, and NI has it all.

Dr. Zhizhong Wang

China Steel Corporation

DAQ Resources: Sensor Fundamentals

Sensors that convert real-world phenomena (such as temperature or pressure) into measurable currents and voltages are essential to data acquisition. Learn more about sensors through practical examples in our tutorials.