Navigating Space Junk Hinges on Test

With 100 million pieces in low-Earth orbit, the risk to satellites and the ISS is significant. Innovative tracking and debris reduction strategies are vital for future space exploration and satellite safety.

The satellites that orbit our planet serve as essential conduits for communication, navigation, weather forecasting, and many other functions integral to modern life. In the vast expanse of space, they face many challenges. From radiation and extreme temperature fluctuations to the ever-present threat of micro-meteoroids, satellites must be built to withstand all of these threats.

To ensure the longevity and optimal functionality of these satellites, engineers have devised ingenious protective strategies and materials. Let’s look at five key tactics that can protect satellites from the multifaceted dangers of space.

One of the most significant challenges satellites orbiting Earth face is radiation. This invisible threat can lead to malfunction, reduced lifespan, or even complete failure. How does radiation damage satellites? Spacecraft charging, which results from the interaction of spacecraft surfaces or their internal components with plasma and energetic particles, can lead to a charge buildup that causes electrostatic discharges, arcing, surface erosion, and even interference with the satellite's sensors and communication systems. Another concern are single-event effects, which arise when a lone energetic particle hits a sensitive area of a microelectronic device, such as a transistor or memory cell. These impacts can lead to various issues like data corruption, bit flips, logic errors, device malfunctions, or even permanent damage.

Satellites are also exposed to the total ionizing dose, the accumulated radiation absorbed by their materials and components over time. This cumulative exposure can degrade the functionality of electronic devices by causing problems like increased leakage currents, reduced gain, amplified noise, and diminished overall functionality. Displacement damage can also occur, which is when energetic particles displace atoms from their lattice sites within the satellite's materials, altering their electrical and mechanical properties. Such changes can manifest as increased resistivity, decreased carrier mobility, heightened brittleness, and reduced thermal conductivity.

Radiation damage to satellites can also be shaped by weather events. Weather in Earth's orbit impacts radiation levels for satellites by altering the upper atmosphere's density and temperature, affecting satellite orbits and communications. Space weather events like solar flares and coronal mass ejections introduce further variables, affecting radiation by heating the upper atmosphere or causing geomagnetic storms. This dynamic space environment poses operational challenges for satellites, making it crucial to monitor and understand space weather's effects to ensure satellite safety and functionality.

Thankfully, there are several materials that can be used to shield against radiation threats:

Satellites in Earth's orbit are exposed to vast temperature variations, making thermal control systems indispensable for their optimal functioning. Such systems are meticulously designed to regulate heat and ensure the longevity and efficacy of the satellite's components.

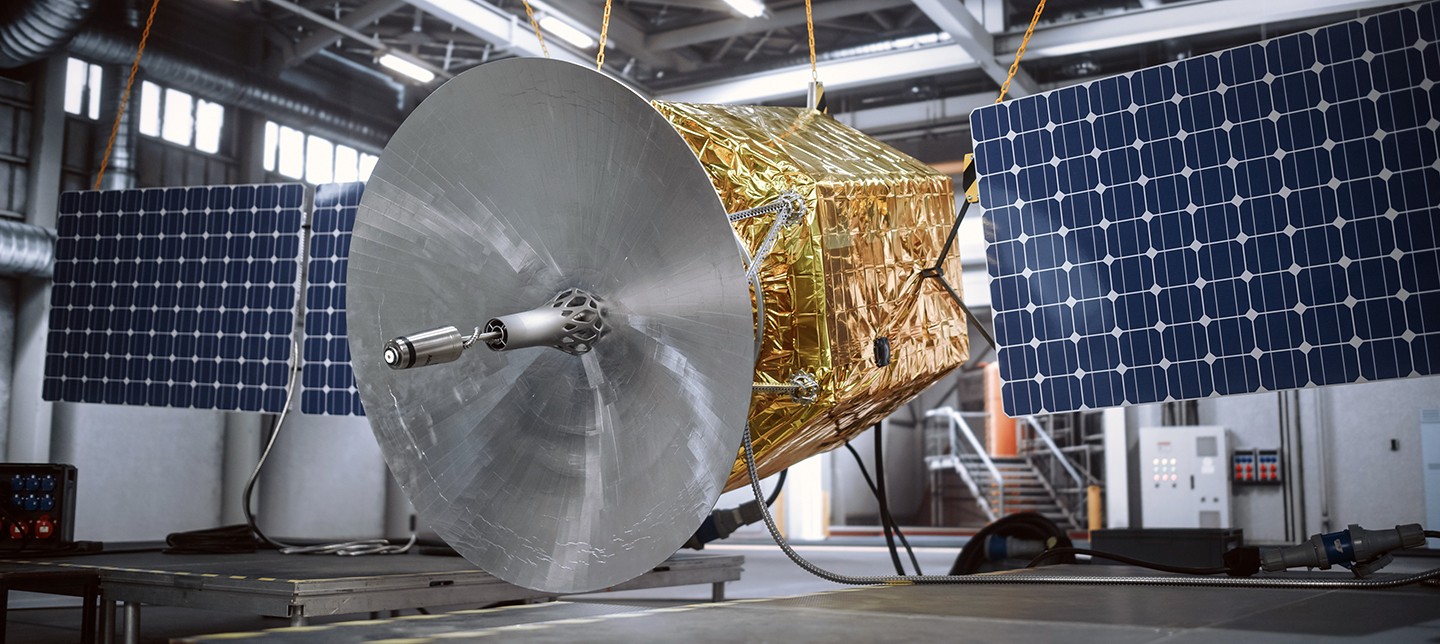

Thermal insulation and reflective materials protect Earth-orbiting satellites from extreme temperature fluctuations in space by reducing the heat transfer of radiation, which is the dominant mode of heat transfer in vacuum. Thermal insulation consists of multiple layers of thin sheets, often made of plastic films coated with aluminized or gold-colored reflective materials. These layers reflect most of the incoming and outgoing thermal radiation, creating a thermal barrier between the satellite and the space environment. Reflective materials also help control the absorption and emission of radiation by the satellite, which can affect its temperature and power balance. By using thermal insulation and reflective materials, satellites can maintain a stable and comfortable temperature range for their instruments and equipment, which are sensitive to thermal stress and damage. Thermal insulation and reflective materials are also lightweight and flexible, which are desirable properties for satellite design and launch.

In addition to insulation and reflective materials, radiators, heaters, and coolers play a crucial role in safeguarding satellites in Earth's orbit from temperature extremes.

Radiators work by managing their heat balance. These devices, typically large panels affixed to the satellite or separate structures, disperse heat from the satellite components into space through thermal radiation. Radiators have two main types: passive and active. Passive radiators, simpler and more reliable, use materials and design to reject heat. They use methods like heat pipes or optical solar reflectors. In contrast, active radiators employ mechanisms like heaters or thermoelectric coolers to adjust the heat transfer based on the satellite's needs. This thermal control, besides preserving sensitive equipment from heat damage, also trims down satellite bulk by negating the need for dense insulation materials.

Heaters and coolers are vital active thermal control systems for Earth-orbiting satellites, ensuring balanced heat regulation. Heaters, typically thermostatically controlled resistive units, maintain equipment temperatures above their lower thresholds during colder mission phases like eclipses. On the other hand, coolers dissipate excessive heat from high-heat-generating equipment to radiators, which then release it into space; common cooler types include cryocoolers and thermoelectric coolers. This thermal management ensures a stable temperature for satellite instruments, sensitive to thermal fluctuations, and aids in reducing satellite mass by removing the requirement for heavy insulation, thereby managing the extreme thermal conditions in space.

Micro-meteoroids, high-speed space particles, pose a threat to satellites in Earth's orbit by causing potential damage ranging from holes and cracks to dents and deformities, impacting their functionality and longevity. These strikes produce immense heat and pressure, even leading to the vaporization of the impacting and impacted material, forming a potentially harmful plasma. To safeguard satellites from these threats, engineers implement strategies like multilayered shielding and applying special coatings.

Whipple shields, named after their inventor Fred Whipple in 1947, are a specialized form of spaced armor shielding designed to protect from micro-meteoroids and orbital debris. With a thin outer bumper distanced from the main satellite wall, these shields function by fragmenting and dispersing the incoming particle. They effectively dilute the impact energy over a broader wall area, enhancing its resistance. When a micro-meteoroid hits the thin foil-like bumper, it vaporizes into a plasma that disperses rapidly. Recognized for their lightweight and efficacy against swift, small particles, Whipple shields have various adaptations, including multi-shock shields with several spaced bumpers and stuffed Whipple shields with a filling of high-strength material between layers.

Coatings play a pivotal role in safeguarding satellites as well. Acting as a protective shield, coatings are thin layers of material tailored to serve specific functions based on their composition. There are multiple kinds of coatings that can be applied including:

With these protective measures, satellites can better withstand the relentless challenges posed by micro-meteoroids, ensuring their prolonged functionality and resilience in the vast expanse of space.

Satellites in Earth's orbit face multiple threats in the vacuum of space, such as spacecraft charging (described earlier in this article), that can lead to issues like electrostatic discharges and interference with communication systems. Engineers can design various features like pressure vessels, seals, and gaskets to combat these detrimental effects.

Pressure vessels in Earth-orbiting satellites are essential containers designed to hold fluids or gases differing from ambient pressure. These vessels ensure a controlled environment for satellite components. Types of vessels include propellent, pressurant, and oxygen tanks. They are made of metal or composite materials and are different sizes and shapes depending on the satellite’s design.

All types of pressure vessels are crucial for satellite functionality, performance, and longevity.

Seals and gaskets are essential for Earth-orbiting satellites, preventing fluid or gas leakages and protecting against the vacuum of space. Environmental seals, made from diverse materials like metals and elastomers, block contaminants from entering satellite components. EMI shielding gaskets, constructed from conductive materials, mitigate electromagnetic interference, ensuring smooth electronic operations. Propellant tank seals, crafted from robust materials, prevent fuel leakage and incorporate mechanisms to monitor propellant conditions. Collectively, these components are critical for satellite longevity, reliability, and performance.

Through the intricate design of pressure vessels, seals, and gaskets, engineers have effectively addressed the challenges satellites face in the vacuum of space, ensuring their optimal functionality and extended operational lifespan.

Satellites play a crucial role in communication, and comprehensive testing to ensure their reliability is essential. Traditionally, satellite manufacturers have faced challenges in scalability, portability, and efficiency when it comes to test. As satellite designs evolved to accommodate more features, conventional automated test equipment (ATE) systems require regular redesigns, leading to increased costs.

The critical testing and evaluation of flight packages necessitates that they be conducted under varying environmental conditions, such as thermovacuum, vibration, and EMI/EMC. To perform all these types of tests, test engineers must move the extensive ATE setup to different environmental test facilities, a process that is not only time-consuming but also risks errors from potential physical damage.

However, NI PXI-based systems designed around software-defined instruments effectively address this issue. The approach significantly reduces the need for physical hardware, translating to savings in both space and cost. More importantly, its inherent modularity ensures that the test system remains flexible and scalable. For example, where traditional ATE may need two separate generators for different functions, the PXI-based system can accomplish the same tasks with a single wide-bandwidth vector signal generator. Similarly, tasks that previously required both an audio analyzer and an oscilloscope can now be managed with one high-accuracy PXI dynamic signal analyzer.

Another area of satellite testing that posed challenges was the emulation, design, and testing of real-life conditions for the next generation of satellite communication systems. Engineers had to ensure that their designs could withstand the myriad of conditions they would face post-launch. NI's Satellite Emulation solution addresses this challenge by providing tools to emulate various satellite orbit and payload characteristics, ground system settings, operational RF environments, and more. The software even permits independent control of electromagnetic channel properties on multiple emulated channels. The integration of the NI satellite link emulation (SLE) IP with commercially available products such as the modular PXI platform ensures a robust solution for these challenges.

The continued evolution of these protective strategies is paramount not only for the longevity and efficiency of satellites but also for the essential services they provide to humanity.