HENSOLDT Increases First Pass Yield with DAIMsphere Solution Based on SystemLink™ Software

Christoph Strähle, Project Manager Testing Solutions, HENSOLDT

Temur Karbassioun, Head of Customer Service, HENSOLDT

LinkedIn: https://linkedin.com/company/hensoldt

Twitter: https://twitter.com/hensoldt

YouTube: https://www.youtube.com/c/HENSOLDT

Case Study Highlights

HENSOLDT resolves ongoing Aerospace and Defense challenges when it comes to collecting fragmented data silos, as well as handling and analyzing classified data.

HENSOLDT developed DAIMsphere, a commercially available product that allows for data aggregation and information mining (DAIM) using NI SystemLink software as the core infrastructure.

DAIMsphere helps to break down fragmented silos and to establish a single source of truth.

“Testing the next generation of sensor solutions, defense electronics, and aerospace technologies requires not only a complete understanding of our products but also of our test systems and data. NI and HENSOLDT have partnered together, using SystemLink software to create a smarter, more connected fleet of test assets that help us maximize customer value and ensure the mission readiness of our customers for the purpose of staying operational.”

—Mr. Temur Karbassioun, Head of Customer Service, HENSOLDT Sensors GmbH

The Challenge

In the Aerospace and Defense sector, collecting and transferring data across and from different test systems within the entire product lifecycle is difficult, especially if you want to analyze them with one Industrial IoT (IIoT) solution. The systems of the future will produce more and more data, demanding a flexible enterprise system that can handle these high data rates.

The Solution

DAIMsphere can handle and analyze classified/secured data from all security zones within the company network. DAIMsphere also can collect data in real time to detect any potential problems in production or production ramp-ups, which ultimately maximizes value. The DAIMsphere solution helps to break down fragmented data silos and to establish one single source of truth across the board, allowing for profound test data management.

Revolutionizing Sensor Testing with Digital Transformation

HENSOLDT is a leading company in the European defense industry and develops complete sensor solutions for defense and security applications. As a technology leader, HENSOLDT continuously expands its portfolio based on innovative approaches to data management, robotics, and cybersecurity.

Next-generation sensor solutions are becoming more complex, and they are transitioning away from classical hardware-only systems. With the rising number of these software-defined products, the amount of test data is increasing exponentially.

Figure 1: Highly precise production steps like in the microwave factory generate huge amounts of data for quality monitoring and management.

To fulfill the test needs of these next-generation sensor solutions while adhering to any new changes to technical standards, methods and technologies are becoming more important than ever. Production test capabilities play a critical role for quality assurance and continuous product improvement.

There is always a balance between legacy implementations and new innovative approaches that aim to improve existing test environments and infrastructures with the goal of increasing efficiency. A major driver as of late has been the digital transformation megatrend, and the step towards Industrial Internet of Things (IIoT) solutions. This means connected testers and data management, not only for unclassified but also for classified data. Especially in the security and defense industry, the requirements to replace risky decisions based on uncertain information by real data driven decisions become unquestionable.

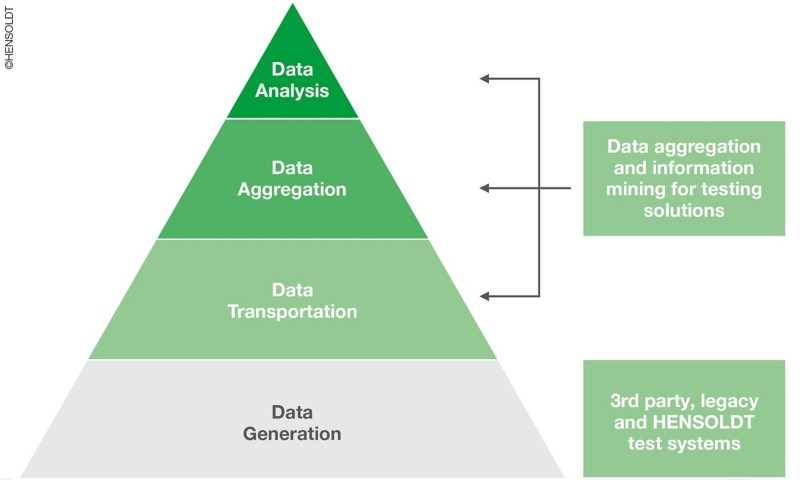

To standardize the data generation layer, the Test Automation Centre (TAC) framework from the HENSOLDT Tester Platform covers the data generation with TestStand as a basis. This data then needs to go through a fully digitalized process to make data-driven decisions. The steps required to make insightful decisions are data transportation, data aggregation, and data analysis.

Figure 2: The DAIM process: The Four Steps of HENSOLDT´s Data Aggregation and Information Mining.

To do so, HENSOLDT has developed a commercially available product called DAIMsphere that allows for data aggregation and information mining (DAIM). The core infrastructure of DAIMsphere is NI SystemLink™. SystemLink software equips enterprises to utilize test and measurement data, remove operational inefficiencies, and uncover actionable insights to improve overall performance across test workflows. SystemLink is a commercial off-the-shelf (COTS) solution based on industry-standard open-source solutions, which is customizable for the specific needs for any digital transformation project.

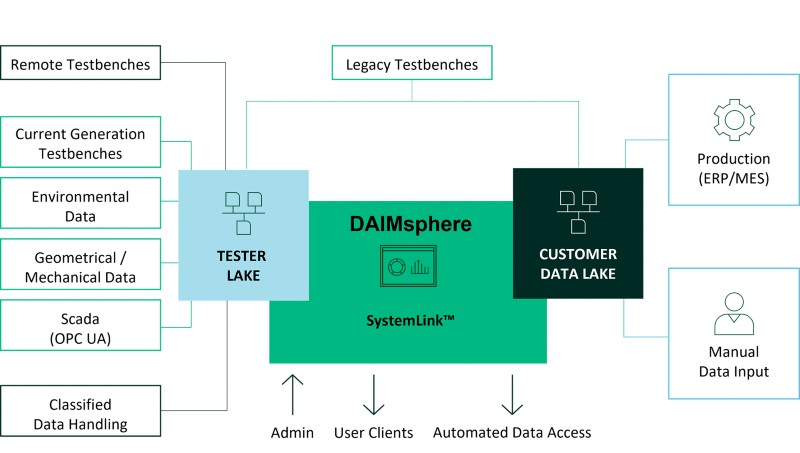

HENSOLDT has developed software components on top of SystemLink that allow for tight integration into customer data lakes and IT infrastructures. This enables connections to current generation, legacy, and remote test systems, and other associated data types—for example, environmental data of the test environment. In addition, modifications in the TestStand framework TAC allow for the secure handling of classified data across all security levels. Finally, the established DAIMsphere framework leads to a standardization for the usage of data across departments, security levels, and involved disciplines like engineering, production, configuration management, and quality management.

DAIMsphere creates a fully standardized Industrial IoT solution for test data and fleet management along the entire lifecycle of the units under test. Its standard functionalities include systems and asset management, test monitoring and insights, and analysis automation and reporting of NI SystemLink. In addition, DAIMsphere adds useful features like intuitive user interfaces, legacy file importer and parsing tools, deployment tools, user rights management, language packs, and automated documentation generator—to name just a few.

Figure 3: DAIMsphere Feature Overview

HENSOLDT is already seeing positive business impacts through digitalizing every quality gate and production step with the DAIMsphere solution. One business example covers line replaceable units for one of HENSOLDT’s radars.

In 2021, HENSOLDT faced the challenge to ramp up a medium-scale production of a new product that had to be tested on more than 12,000 individual test points. Of course, using traditional methods like spreadsheet tools proved to be difficult when handling tens of millions of datapoints. After transitioning to the DAIMsphere Testing Solution and spending approximately 100 hours on data standardization, statistical analysis, and interpretation, the department was able to increase the first pass yield from 40 to 95 percent by adapting test limits during the ramp-up. This optimization is saving HENSOLDT rework and analysis steps for several thousands of units and was achieved by standardized and quality approved, data-based decisions, and concurrent engineering enabled through DAIMsphere. The solution helped to break down fragmented silos and establish one single source of truth across the board.

With the engineering, business and operational advantages, DAIMsphere is commercially available as a software solution. Besides integration support with setup and commissioning at customers and end-users, HENSOLDT provides service packages with life cycle support, including, but not limited to, Technical Assistance, Training Services, Technical Publications, Software Maintenance and Sustainment Services. HENSOLDT’s services portfolio allows customers to maintain the operability and availability over the entire product life cycle, which usually spans many decades.

HENSOLDT and NI Partnership

Thanks to HENSOLDT's expertise in NI’s software capabilities, NI has selected HENSOLDT to serve as a dedicated expert to sell SystemLink.

With this trusted partnership, NI and HENSOLDT will be working together to solve any challenges ahead and provide maximum value to our customers.