Digital Twins Blur the Lines between Physical and Digital Test Engineering

Working with virtual reality to create digital twins and threads offers nearly endless possibilities that companies are just beginning to take advantage of.

NI (formerly National Instruments), headquartered in my hometown of Austin, Texas, is a company I've been following for a long time. In 2020, National Instruments shortened its name to 'NI' along with a cool new logo and company strategy.

NI is best known for automated testing and measurement tools to aid in researching and validating new technologies. Recently the company has reinvented its operating model to focus on software-defined testing systems and the addition of technologies such as data analytics and machine learning. This article is a progress report on how the company is helping customers modernize the product development process with software and the company’s vision for the future of test and measurement.

New product development aims to ensure the end customer receives a quality product and neither the customer nor the manufacturer incurs the recall cost due to product failures after delivery.

As we have evolved to the next level of digital maturity, there's been a significant increase in the complexity of systems. Examples include the move from 4G to 5G in the wireless space, from fifth to sixth-generation fighters in aerospace and defense, to autonomy in transportation, and the proliferation of intelligent connected electronics with the rise of IoT devices.

Delivering complex, higher-performance products to market at lower cost with few to zero defects depends on a company-wide product data strategy that seamlessly integrates product data and analytics across the product lifecycle.

To compete effectively, companies must use all data to improve the product development process, extracting maximum value and using test data to identify critical issues that affect quality and performance.

Customers are dealing with test data coming from NI hardware and other products across different phases of a product's lifecycle. The NI goal is to consolidate data together pragmatically, so customers can perform basic analytics and gain insights to improve the product development process. Basically, to use test data to help improve the product performance.

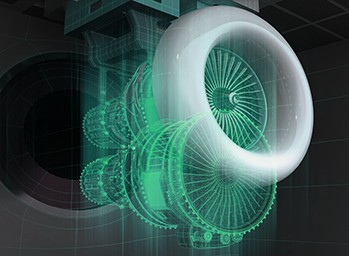

Using virtual reality to create digital twins and digital threads opens up new possibilities for the future of test engineering. A digital thread is a virtual universe that houses the digital twin model. A digital thread enables interconnected models across the lifecycle of a system, with all the models in sync through a shared API.

As the name suggests, a digital twin is a virtual model that accurately reflects a physical object. The object is equipped with sensors to produce data about performance aspects, such as energy output and temperature, that can then be applied to the digital copy. The digital twin can run simulations, study performance issues and generate possible improvements to the original physical object.

A digital thread with interconnected models can substitute for testing in the real world. Testing becomes faster and less expensive, and in some cases, reduces the environmental impact. Moving more of the design into the virtual world enables the exploration of complex products faster and reduces dependence on costly, time-consuming physical prototypes.

These are not futuristic ideas. Siemens Mobility Rail Solutions builds high-speed and commuter trains - expensive costly systems with thousands of components. Siemens uses NI hardware, TestStand software, VeriStand software, and the LabVIEW FPGA Module to build a fully functional digital twin of a whole train. You can find more detail on this story here.

NI is developing a modular software platform assembled via APIs to meet any customer's specific needs. All the software building blocks will run on-premises or in the public cloud. The platform uses security and resiliency frameworks and DevOps tools to deploy products in a simple and lightweight manner both in the data center and the cloud.

The data ingestion service ingests data from all connected systems for analysis. Once ingested, the data is subjected to the correct persistent data service (an API implemented through REST), whether it be time series, waveform, parametric, or other future data formats. The persistent data service uses polyglot persistence to use the right store, whether it be SQL, NoSQL, or object stores.

The architecture will include an analytics and machine learning (ML) layer consisting of a collection of ML frameworks like Kubeflow and Spark R used to build machine learning models. NI will provide models templatized to reflect the best practices in the industry. There will be a choice of familiar analytic tools such as Microstrategy, Tableau, and Power BI.

The visualization layer is connected to or embedded with standard tools and a UI framework layer. The UI framework consists of Angular and other building blocks to deliver a simplified user experience in any browser or mobile device.

Again, this is not all futuristic. General Motors is working with NI on its battery cell engineering process to provide visibility into test data to make decisions on optimizing product performance. GM is investing in a web-based, cloud-computing toolset; personnel; and a data platform that includes NI SystemLink™ software as part of the architecture. The scalable solution will save thousands of hours of manual work by automating the end-to-end process from data ingestion to making it available on-demand. You can find this and other stories here.

Shifting the NI company strategy towards modernizing test and measurement with software, cloud, and machine learning capabilities creates value for customers. Additionally, moving the entire organization to focus on four markets: semiconductors, transportation, aerospace, defense, and the government, was also a brilliant move.

Increasing product complexity requires more detailed insights into the product and its behavior. Test data provides many answers, but this valuable asset is often not utilized to its full potential.

There is power in test data when used effectively, as opposed to just storing it on a hard drive. Test data can optimize production processes and even improve product design. Test data can be fed into simulations to improve accuracy, identify bottlenecks in manufacturing operations, increase product quality and decrease the time to market.

The NI charter is to take the liability of collecting and storing test data and convert it into a powerful asset that adds value back to the organization. Essentially unlocking the value of data across the complete product lifecycle from design, validation, production, and in-use will be critical to success and competitiveness. NI has a wide range of tools across the entire design process that integrates seamlessly with third-party tools that a customer may already have in design labs and simulation environments.

This article was originally published by Forbes.