Electronics Case Studies

Discover how engineers leverage NI hardware and software to efficiently validate and perform high-volume production testing of electronic devices.

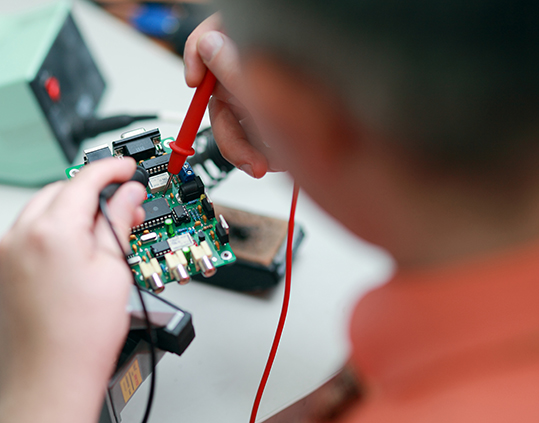

Validation

Discover how to use NI hardware and software solutions to accelerate the validation process of electronic devices, ensuring shorter time to market and enhanced testing efficiency.

Landis+Gyr designed an automated testing framework system to run functional tests for smart meter metrology validation while reducing test system time and cost.

Opalum created a scalable sound optimization system to test sound quality within constraints such as small devices and strict power consumption requirements.

Whirlpool built a stand-alone smart system to acquire information and manage washing machine cycles to help develop a silent washing machine.

Researchers built a fully automatic measurement system to test up to 50 magnetic couplers simultaneously while they are subjected to high voltage and temperature.

Peratech designed and implemented a secure, automated, data-driven testing and monitoring system that can be used in any facility manufacturing force sensors.

SOCOMEC SA used NI hardware and OPAL-RT to create a real-time, high-performance hardware and software HIL validation solution.

Researchers automated the safety test processes using pneumatics to test the mechanical operation and sensors to read the status of a device’s electrical circuit.

Cypress Semiconductor Technology India Pvt. Ltd. developed an ATE-like platform called CyMatrix to reduce bench characterization of system-on-chip (SoC) products.

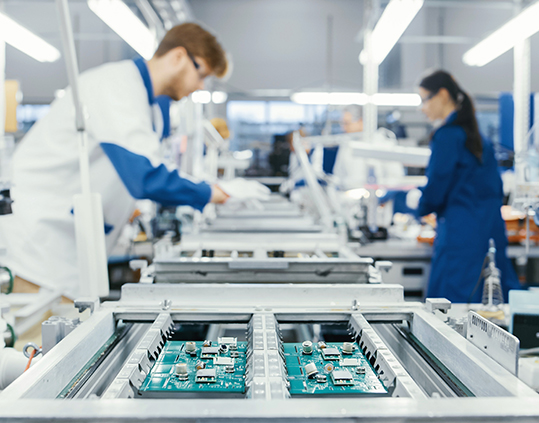

Production Test

Learn how to leverage NI high-volume manufacturing test solutions and advanced analytics to optimize electronics yield, enhance product quality, drive efficient production processes, and reduce total cost of ownership.

Circuit Check Inc developed a modular, clean room-compatible automated test system for industrial inkjet printing, capable of simultaneously testing six print heads.

Microsoft developed an end-of-line, low-cost production test system for the Xbox 360 wired and wireless controllers with data storage to the Microsoft SQL Server.

Philips developed a standardized platform to meet test stations’ needs and reduce development schedules while maintaining or increasing test coverage and quality.

GN Audio standardized a production test platform that uses CIM and NI COTS products to reduce new test development time from months to weeks.

Researchers created a rugged real-time test bench for operating with robots and performing testing and monitoring according to robotic machine safety regulations.

Amfax developed an XYZ measurement-based inspection technology to help companies improve the quality of their manufactured PCB assemblies.

Researchers utilized NI SourceAdapt technology to make an LED tester five times faster than others composed of a traditional rack-and-stack source measure unit (SMU).

WKS Informatik created an automated test system that reduces test times and costs and provides insight into ECU behavior during electrical tests for validation.

Panasonic developed a software-defined test system to improve Toughbook quality while reducing test development time and environmental impact.