With Ultium, GM is consolidating on a platform to build a variety of EVs, from a pickup truck to a luxury SUV to a commercial delivery vehicle. As expected, this consolidation offers large benefits of scale, but it also presents the big responsibility of ensuring every single component is the best it can be regarding safety, cost, and performance. This is especially important for the battery, down to every single cell.

To safeguard the quality of every cell on every pack, GM is working with NI on its battery cell engineering process to give its engineers visibility into all test data so they can make decisions to optimize product performance.

Automotive Data Enables Scale

The EV battery holds the secret to enable electric vehicle adoption at scale, so test teams feel a lot of pressure to define and execute test plans and quickly use insights from the test data to make decisions and safely speed up development and deployment. But how much battery data needs to be analyzed to truly have zero blind spots and achieve this scale?

To get an idea, consider this example. A Hummer EV battery pack contains 24 modules with eight cell groups per module. Each cell group requires a voltage measurement about 10 times per second, resulting in 1,920 voltage measurements being collected every second. Finally, these tests can run up to a year. Multiplying for every second in 365 days, you get 60,549,120,000 voltage measurements per year—well over 60 billion measurements just for voltage. Now add the many other measurements like current or temperature, and you get a better idea of how much data needs to be analyzed to be used, just from test. However, to fully test an Ultium battery pack to the standards of safety and performance GM is committed to, data from other processes, test stations, manufacturing, etc., will need to be used. This means that engineers must deal with not only a huge amount of data but also a large variety of formats.

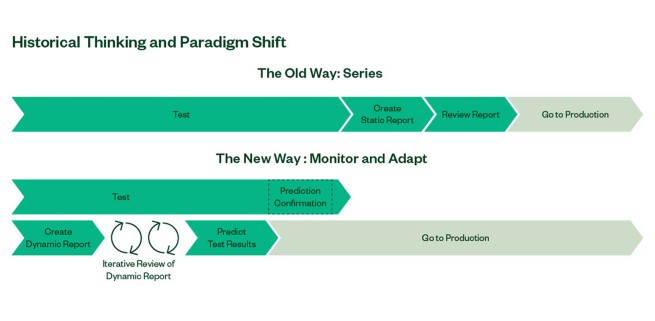

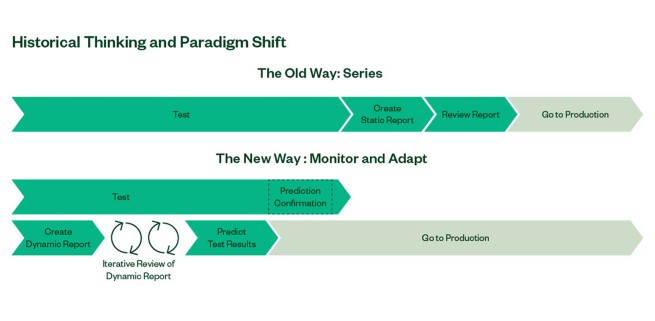

The end-to-end process to extract the insights from all this data to make it useful to GM engineers involves data ingestion, aggregation, contextualization, engineering, processing, and tagging, among other steps. With traditional solutions, this may all be possible, but traditional methods will not help you achieve the scale and speed needed. A paradigm shift is necessary.

FIGURE01: Using data to enable scale and speed requires a paradigm shift from sequential processes to a continuously monitored and adaptable process.

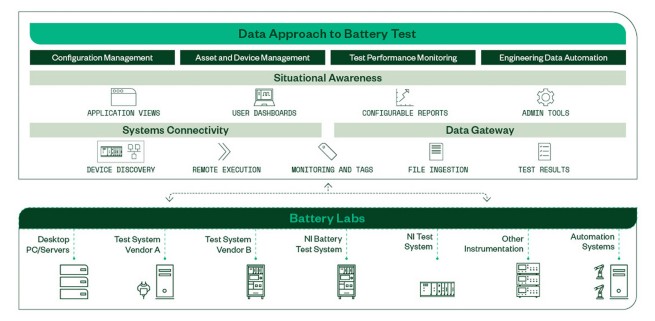

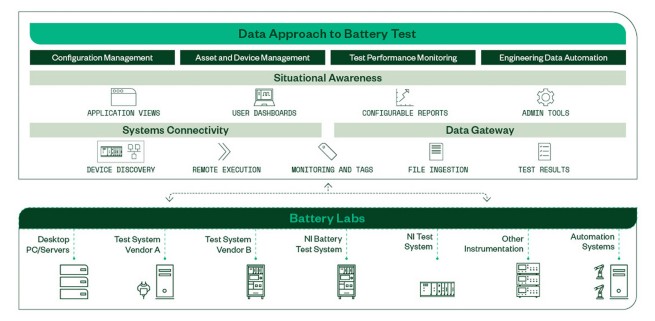

To enable this ability, GM is investing in a web-based, cloud- computing toolset; personnel; and a data platform that includes NI SystemLink™ software as part of the architecture. The data platform must be:

- Secure to protect the insights of GM’s battery cell engineering through access control, authentication, and encryption capabilities

- Scalable to save thousands of hours of manual work by automating the end-to-end process from data ingestion to making it available on-demand; this would preserve the flexibility and independence for GM engineering needs

- Open to ensure sustainability, compliance, and compatibility with GM’s IT infrastructure so that GM engineers can use open-source tools, different databases, and programming languages as well as define the dashboards and customization they need to analyze automotive data and generate insights

With NI’s SystemLink™ software, we can deliver our test data to all engineers in a secure and easy way to enable them to view their data and save templates for follow-up tests— all in near real time.

- Ciro Spigno, Group Manager, Battery Systems and Analytics, GM

GM’s data platform will heavily use SystemLink’s attributes to provide engineers with the data they need and the ability to use it to improve GM’s EV components. Additionally, the compatibility with GM’s IT infrastructure will make it sustainable and provide a path for GM to be vendor-independent as the company continues to grow its battery cell operations.

FIGURE 02: NI’s data approach to battery test automates the end-to-end process to help engineers derive insights from test data.

Commitment to Test Data

At NI, we believe that data elevates the role of test from a pass/ fail process to an enabler of product performance, so we continue to invest in EV test and lifecycle analytics solutions to enable automotive market leaders like GM transform their businesses and help the world get to an all-electric future faster.