Power Semiconductor Reliability Test

Benefit from the Latest Test Technologies

As a technology leader in dynamic testing of power semiconductors, NI is committed to addressing the industry’s evolving needs. Leveraging our vast experience and collaborations with customers, academia, and industry groups like ECPE AQG 324 and JEDEC JC-70, we aim to contribute to the future safety of mobility by defining test standards. Our Power Semiconductor Reliability Round Table provides a valuable platform for knowledge exchange and industry advancement.

FEATURED SOLUTION

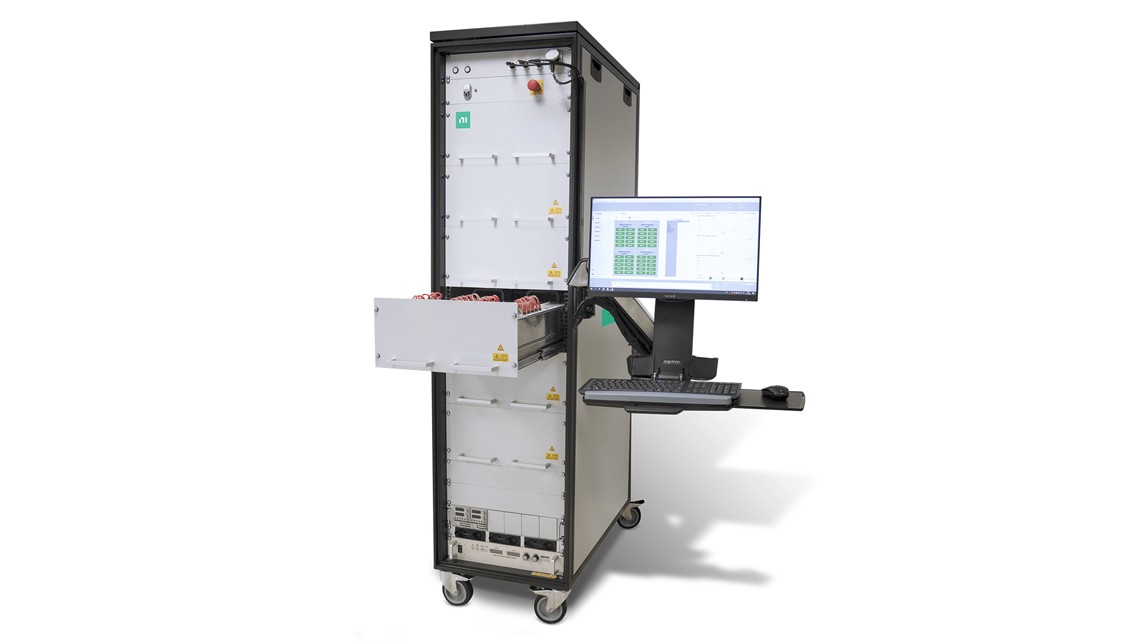

Power Semiconductor Reliability Test DGS

Silicon carbide (SiC) and gallium nitride (GaN) power semiconductors require new dynamic testing methods because of unseen failure mechanisms in wide-bandgap materials affecting real applications. Dynamic gate stress (DGS) tests close this gap, surpassing static test methods with a stronger application focus.

Enhanced DGS Testing for SiC and GaN Semiconductors

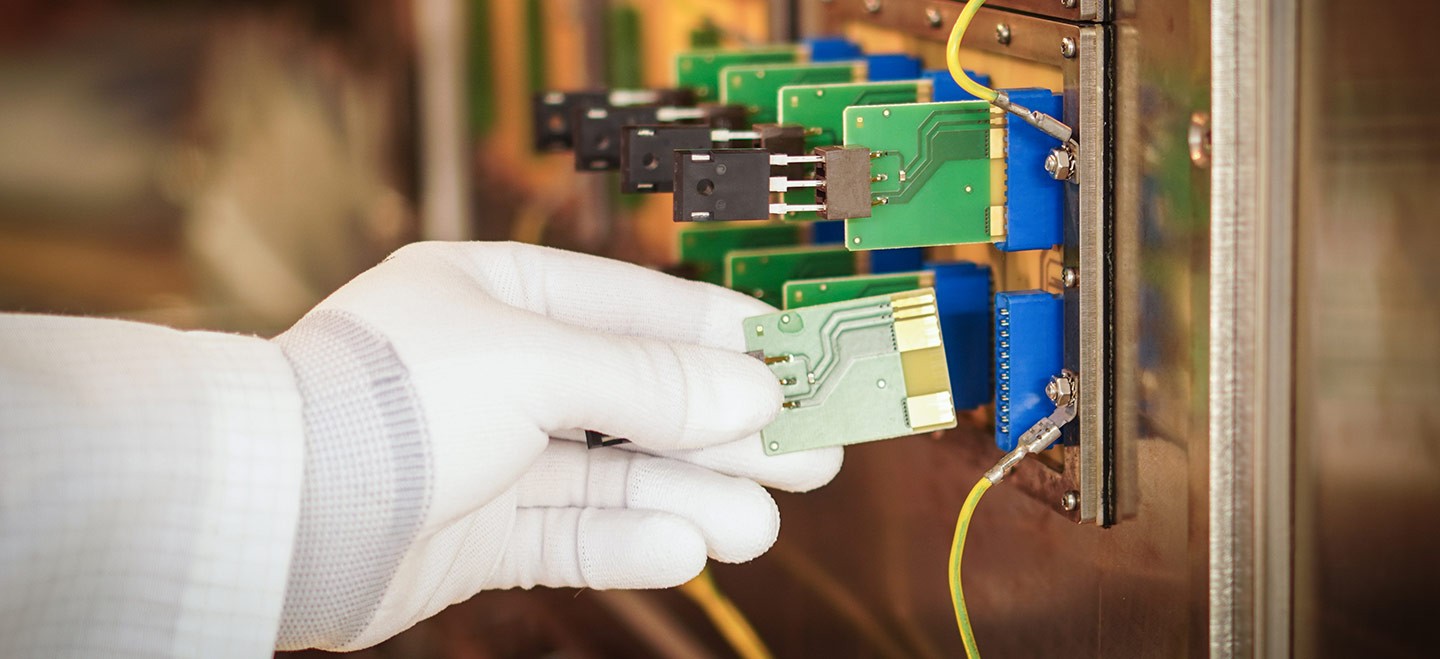

Application-Oriented Testing

The use of wide-bandgap components and the challenges of qualification are increasing exponentially. SiC and GaN power semiconductors introduce new failure effects, resulting in additional testing challenges. Dynamic tests such as DGS, dynamic H3TRB, or DRB are closer to the real application. These tests help to detect faults like drifts at an early stage before the component goes into series production and causes recalls. However, they also offer new challenges in concrete implementation. Scaling these tests for larger batches and accurately capturing failure mechanisms to develop effective models remains challenging. We provide the latest test methods and guidance on their implementation for component testing and qualification to ensure the safety and reliability of your power semiconductor devices.

Related Content