Upgrading a Wind Tunnel Test System With NI LabVIEW and CompactRIO

鍾恕 系統工程師, 星協系統科技

"We chose NI LabVIEW software, a programming language based on data flow, not only because multithreading is an innate function of the software but also because LabVIEW features FPGA and real-time integration to easily meet system needs."

- 鍾恕 系統工程師, 星協系統科技

The Challenge:

Updating a large, low-speed wind tunnel test system that exhibited unsteady control and was complicated to operate.

The Solution:

Using NI CompactRIO hardware and LabVIEW software to develop a smaller, more powerful wind tunnel test system with a more stable control system and simpler operation.

Author(s):

鍾恕 系統工程師 - 星協系統科技

吳志二 專案經理 - 星協系統科技

蔣步勤 系統工程師 - 星協系統科技

王崇駿 電路工程師 - 星協系統科技

呂芳仁 總經理 - 京祐科技

Eric Chung - WPC Systems Ltd.

Buqin Jiang - WPC Systems Ltd.

Chongjun Wang - WPC Systems Ltd.

Zhi’er Wu - WPC Systems Ltd.

Fangren Lv - Jing You Technology Co., Ltd.

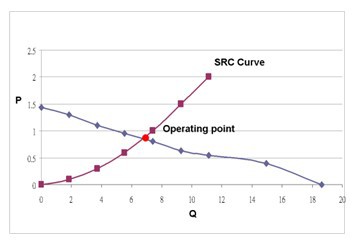

Recently the design of heat dissipation modules has been in the spotlight. Although the fan plays an indispensable role in these modules, there are still no standard criteria for its design. If researchers quantify fan performance, they can use the test data to analyze and optimize the design and considerably reduce development time and costs. With wind tunnel tests, researchers calculate fan output performance using pressure-quantity (P-Q) curves and system resistance curves (SRCs). The junction point of two curves is the optimum operation point matching the system resistance. Because of this, fans and heat vents should undergo wind tunnel tests to determine how to improve fan blade design and heat vent configuration.

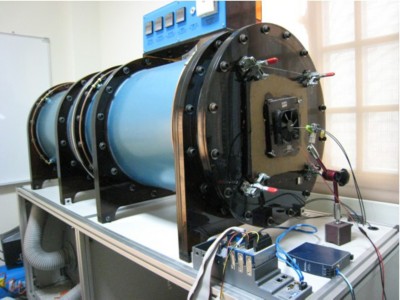

Wind Tunnel Test System Components

A wind tunnel test system is the best device to measure P-Q curves and SRCs. The system consists of the following subsystems:

- Wind tunnel body – conducts flow stabilizing and ambient control

- Measuring system – provides temperature, humidity, and atmospheric pressure measurements as well as the chamber temperature and pressure

- Spray nozzles switching system – helps avoid low velocity by choosing the appropriate nozzle

- Flow control system – ensures that the system’s pressure and air flow are in a steady state

- Fluid mechanical parameters calculation and processing system – the P-Q curves and SRCs are determined due to ambient parameters measured when calculating the fluid mechanical parameters

- Human machine interface

Modernizing a Wind Tunnel Test System

Jing You Technology Co., Ltd., previously Yu Jia Technology Co., Ltd., is a professional supplier of wind tunnel test systems in China and has devoted years of research to the development of wind tunnel test systems, heat dissipation modules, and relevant fluid mechanics tests. Although the company has extensive experience and knowledge of the latest technologies in wind tunnel test fields, until recently, Jing You Technology still offered its customers its original test system, which is based on industrial personal computers (IPCs), programmable logic controllers (PLCs), and customized circuits. This platform’s many disadvantages include unsteady control, low speed, complicated operation, and large size. Jing You Technology asked NI Partner WPC Systems Ltd. to help upgrade its former IPC platform to an NI programmable automation controller (PAC) platform using CompactRIO.

Application Solution

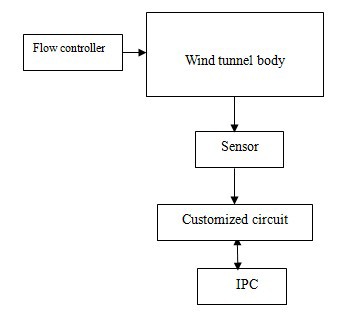

The application system consists of hardware and software. The framework of Jing You Technology’s former IPC system is depicted in Figure 2.

Hardware

The accuracy of the control system worked well enough for industrial test, but we needed to improve the control stability and speed. For example, the system deadlocked when the flow control and spray nozzle switching systems tried to work together. After analysis, we determined that the two main reasons for this were a dynamic range matching problem and a time delay problem that occurred when we measured the physical parameters.

Because the IPC, which worked as the main machine of the system and conducted all of the measuring and control processes, and the rest of the system did not run in real time, a time delay inevitably occurred in both the measuring and control processes. Additionally, pressure difference, the most important parameter the wind tunnel system tracks, was measured by the real flow system and was not always in a steady state. As a result, some systematic parameters such as pressure and density of the flow were formed by the superposition of many modal waves. To ensure data accuracy and avoid aliasing, we knew we had to increase measuring speed and conduct many parallel-group trials to reduce the random data obtained by the system.

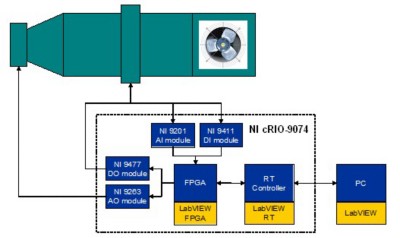

We chose the NI 9201 C Series analog input module, featuring a 500 kS/s measuring speed, and the NI CompactRIO field-programmable gate array (FPGA) platform for the new system. With this hardware, we can achieve high-speed signal solutions to make sure that the measured pressure values reflect the system condition in real time and the measured system data remains at average levels. Because the NI 9201 has eight independent channels, we do not need additional modules to measure the pressure and temperature.

Apart from measurement, flow control is the most important part of the system. In the former system, voltage commands were used to control the inverter which in turn controlled the air blower exhaust. To make the flow control more accurate, we chose the NI 9263 C Series analog output module with 16-bit resolution and 100 kS/s voltage control. We also used the NI 9411 and NI 9477 C Series digital I/O modules to control all of the switches and digital detectors.

Software

Software also plays an important role in the system and performs the following functions:

- Accurate measurement and signal processing

- Steady real-time control of the air exhaust and spray nozzle switching

- Quick achievement of steady control

- Easy operation

We needed software that could synchronize control in different parts of the system as well as perform continuous high-speed measurement and signal processing. The flow control system had to conduct uninterrupted, closed-loop control on the air blower to maintain steady pressure and system temperature. Closed-loop control is used on the fan when measuring at a fixed rotation rate. The safety devices had to detect runaway situations in real time. We also needed software that offered multithreading so each subsystem is independent and can communicate with each other to work synchronously. We chose NI LabVIEW software, a programming language based on data flow, not only because multithreading is an innate function of the software but also because LabVIEW features FPGA and real-time integration to easily meet system needs. Furthermore, FPGA and real-time controllers are built into the CompactRIO system.

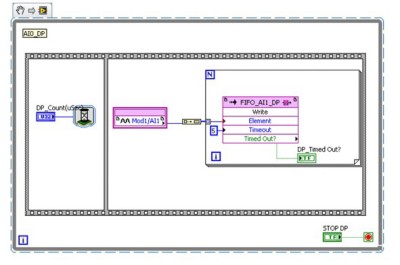

New Wind Tunnel Test System Framework

To meet software function requirements, we developed the system framework based on LabVIEW and the LabVIEW FPGA and LabVIEW Real-Time modules running on a PC, as shown in Figure 5. Because of the seamless integration between the FPGA on the CompactRIO module and the other modules we chose, the high-speed digital signal processing can be implemented directly with LabVIEW FPGA to obtain steady pressure and flow values.

We also chose LabVIEW Real-Time to ensure steady real-time control. From the CompactRIO real-time controller, every pressure value measured sends a response to the system. The pressure can then be controlled accurately within a certain range by the air blower. With real-time control like this, no delay occurs and the main factors that caused the unsteadiness of the former system are avoided.

Although system control is easy, the point at which to switch the spray nozzles still depends on accurate system decision making. If the system decision-making mechanism is not designed correctly, the following results may occur:

- A system timeout without warning

- Unpredictable measuring time

- Spray nozzles switched repeatedly

- Inconsistent measurement data

- Longer test speeds

Nozzles with different sizes correspond to different dynamic ranges of measurement; therefore, the measurement accuracy is greatly affected by nozzle switching. The following factors must be considered when switching nozzles:

- Whether the static or dynamic pressure of the system is within the limit pressure range of the system

- Whether the output of the air blower exceeds the limit range

- Whether the flow velocity of the system is below the measurement limit

In a suitable decision-making process, the nozzle switching and decision making are combined with the threading of the flow control. The real-time controller is used to make decisions in real time, so the nozzle switching problem is solved rapidly.

With the remote online functionality built into the CompactRIO system, the minicomputer (which is like a notebook) can easily connect to the updated wind tunnel controller to take the measurements. The large IPC is no longer required. The updated wind tunnel test system using CompactRIO and LabVIEW has more powerful functions, a smaller size, and more stable control and convenient operation.

Conclusion

By changing the wind tunnel test system platform successfully from an IPC to a CompactRIO controller, we at Jing You Technology and WPC Systems simplified the wiring of the whole system and decreased the total system size by about 33 percent. We used only one CompactRIO controller to replace the IPC, PLC, customized controller, PWN controller, tachometer, and ammeter. Additionally, we reduced costs by 25 percent and increased test speed by about 50 percent. We lowered the development time costs using LabVIEW software and simplified the operation with the LabVIEW graphical user interface. In addition, we used the powerful LabVIEW Report Generation Toolkit for Microsoft Office, which combines measurement, analysis, and reporting functions, for the heat dissipation modules. The user needs only cables and notebooks to immediately conduct the fan test and generate test result reports.

Author Information:

鍾恕 系統工程師

星協系統科技

chung@wpc.com.tw

An NI Partner is a business entity independent from NI and has no agency, partnership, or joint-venture relationship with NI.