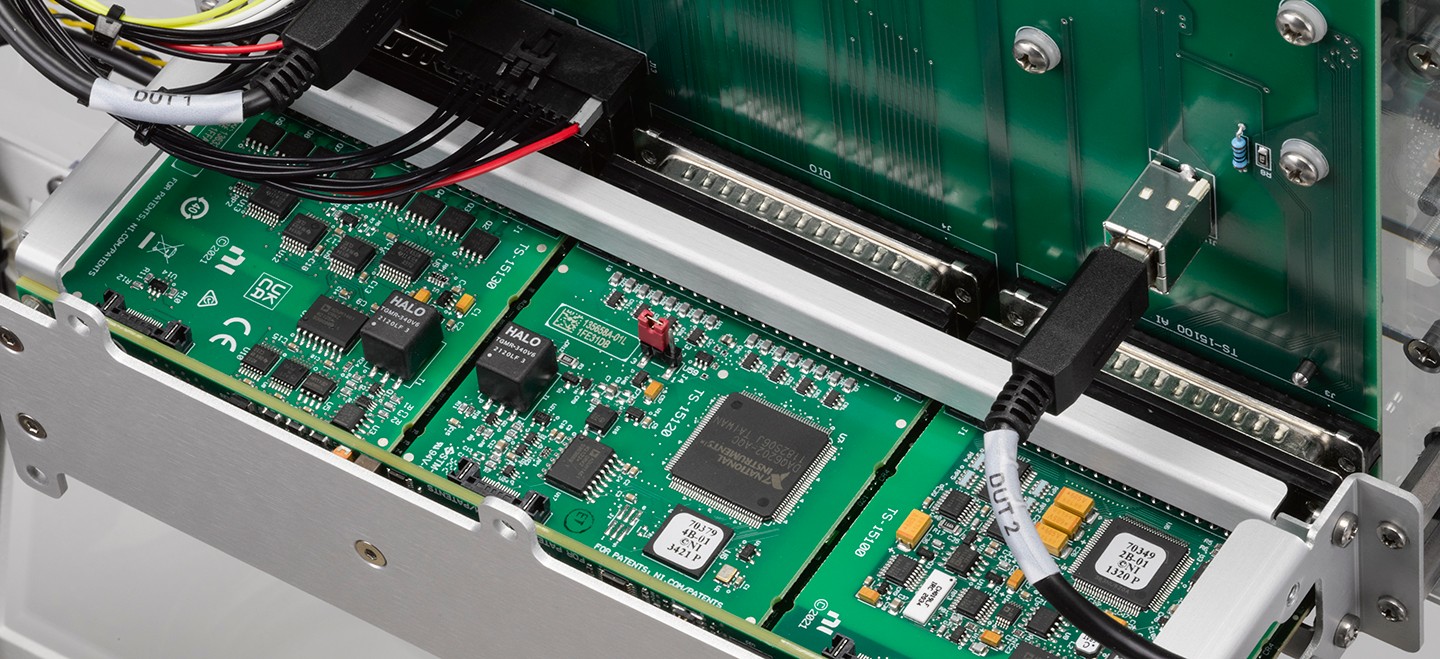

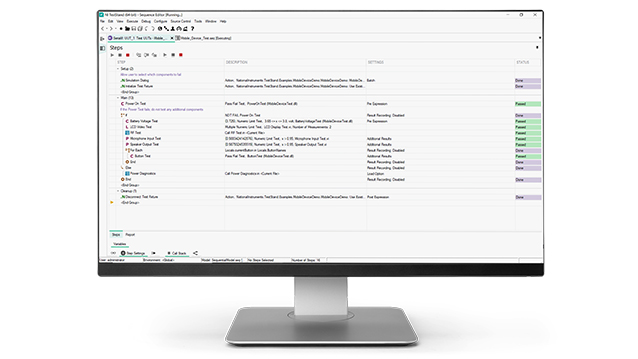

From interactively capturing and exploring your data to programming a fully automated measurement system, seamless software integration lets you tailor tests to your needs. We designed TestScale to work with TestStand™, SystemLink™, and programming environments such as LabVIEW™ to help you meet development requirements and spend your time on what matters most. Since TestScale hardware also uses the powerful NI-DAQmx driver, you can program it with the language of your choice. The TestScale Soft Front Panel (SFP), a software add-on for InstrumentStudio, can help you configure and execute measurements.