Save Time and Maximize Reuse in HIL Testing with the SLSC Extension for PXI and CompactRIO

Overview

NI SLSC (Switch, Load and Signal Conditioning) is an add-on for NI data acquisition products like PXI and CompactRIO. SLSC standardizes connectivity and provides a modular approach to signal conditioning, fault insertion and other test needs. This white paper discusses the details of SLSC and showcases the growing ecosystem of SLSC modules and accessories created by NI and NI partners.

Contents

What is SLSC?

As technology advances, embedded software is becoming increasingly prevalent in complex, safety critical systems such as automobiles and aircraft. Hardware-in-the-loop (HIL) testing is a methodology adopted by many industries to test embedded software while simulating the real-world inputs to that system. This approach allows testers to test early and often without risking damage to costly hardware and without incurring safety risks associated with unvetted product.

Because successful HIL testing hinges on accurately simulating real-world signals, custom signal conditioning and in-house development of simulated loads to guarantee signal integrity has been the norm. While it’s true that no one is as knowledgeable about specific test requirements as the test engineer working on the system, NI has observed that much of this custom engineering is common across companies and industries. This observation lead to the development of SLSC, an add-on to NI’s powerful measurement and control platform that streamlines signal conditioning and test stimulus needs.

SLSC Extends the Functionality of Measurement and Control Hardware Such as PXI

SLSC extends PXI and CompactRIO and consists of a chassis with modules. Each module has a Rear Transition Interface (RTI) which provides flexible standardized connectivity from SLSC to PXI or CompactRIO. Additionally, an SLSC system has a standard pinout that allows for the use of standard cables and eliminates point to point wiring.

SLSC plug-in modules can operate in the chassis in three different modes: stand alone, pass through, or cascaded. Cascaded mode can be used to cascade the signal path through multiple SLSC modules and implement functionality like signal fault insertion. You can choose from a variety of third-party modules or create your own modules based on a detailed hardware and software module development kit (MDK) from NI.

SLSC hardware is designed to simplify overall system integration by reducing system point-to-point wiring through signal accumulation and standard cable use. Each SLSC chassis consists of an SLSC digital bus, which you can use to discover, configure, and set parameters on the individual modules. Signals pass through SLSC modules either from the front connector or the rear transition interface (RTI) connector. You have the flexibility to design your own secondary backplane RTIs to reduce system wiring.

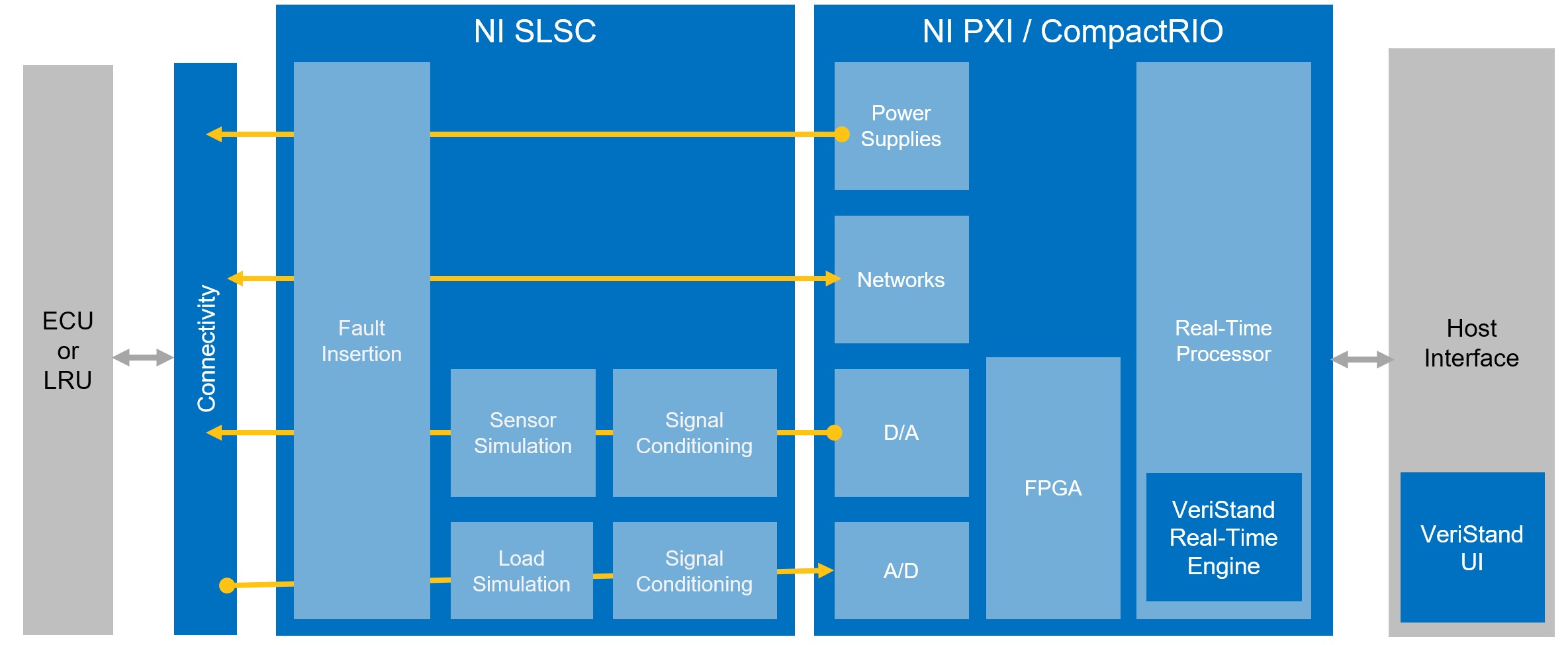

HIL System Diagram with SLSC

SLSC sits between the DUT/UUT and the data acquisition device you’re using

An SLSC system is comprised of four different component types: chassis, modules, rear transition interfaces (RTIs), and cables. The chassis and architecture have been designed and are produced by National Instruments with both NI and partners producing components that complete the ecosystem.

- SLSC Chassis – The SLSC chassis in conjunction with PXI is designed to handle more power and provide more board footprint than PXI alone, which makes it ideal for high power loads, switching, and signal conditioning. The chassis handles communication to the modules as well as mechanical fixturing and cooling.

- SLSC Modules – SLSC modules provide the switching, load simulation, or signal conditioning for the signal paths. Modules can communicate and be powered through the SLSC chassis or through auxiliary lines on the modules themselves.

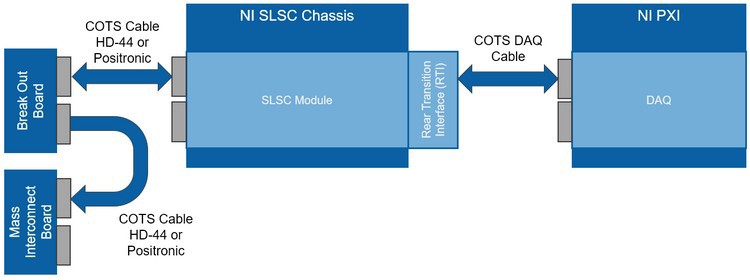

- Rear Transition Interface (RTI) – The RTIs provide standard connectivity from SLSC modules to commercial off the shelf (COTS) cable options and back to DAQ modules. RTIs are generally SLSC module agnostic and are chosen based on the connectivity and cabling desired to bring signals back to the PXI or cRIO system.

- Cabling – One of SLSC’s greatest strengths is reducing time consuming and expensive point to point wiring by allowing signals to be passed around through banks within standard available cables. A variety of cables exist within the SLSC ecosystem that allow you to appropriately split out and combine signal paths.

An example system diagram of SLSC components and their interface with a PXI DAQ card

The Growing SLSC Ecosystem

NI brings automated test and automated measurement expertise from an array of industries. This broad expertise allows us to create technology like SLSC from our observations of cross-industry needs. However, you need products that are targeted to your specific application. That’s why SLSC, designed to be an open platform, is enhanced by modules created by NI, our partners, and you through our module development kit (MDK).

Our partners, like Bloomy who has created a MIL-STD-1553 module for SLSC, bring domain expertise that yield products that are specific to your industry and unique test needs.

Below is a list of products currently available for SLSC from NI and NI partners. Due to the complex nature of HIL systems, please contact us for assistance when reviewing the technology listed below. NI and our Alliance Partners are dedicated to ensuring your test requirements are met.

Core Components

- Chassis for SLSC—The Chassis for SLSC provides power, active cooling, and a communication interface to SLSC modules.

- Module Development Kit for SLSC—This MDK helps you design and develop custom switch load signal conditioning (SLSC) modules and rear transition interfaces (RTIs).

Modules

NI offers prototyping, digital I/O, routing, fault insertion modules, and more. For a full list, visit our SLSC products category. In addition, many NI partners offer SLSC modules that you can incorporate into your system.

- Bloomy provides a thermocouple simulator, load module, multipurpose module, and more.

- Aliaro offers a multifunction module for automotive as well as a CAN/LIN/Ethernet Bus Switch Board, along with other options.

- Opal-RT has developed SLSC modules for analog and digital I/O, including FIU and pass-through options.

Other Components

| Rear Transition Interfaces* | NI Part Number | Vendor | Description |

|---|---|---|---|

| RTI-12301B | 786330-01 | NI | RTI DIO 32 for SHC68-C68-RDIO2 Cable |

| RTI-12302 | 785377-01 | NI | 64 Ch for RDIO2 |

| RTI-12303 | 785375-01 | NI | DIO/AO/AI X 4 Bank Nanofit |

| RTI-12304 | 785374-01 | NI | DIO 37DSub |

| RTI-12344 | 785376-01 | NI | AO 37DSub |

| RTI-12305 | 785896-01 | NI | HD44 Connector |

*See module user manuals for RTI recommendations.

| Cables* | NI Part Number | Vendor | Description |

|---|---|---|---|

| SHC68-C68-RDIO2 Cable | 156166-01 | NI | 1 meter |

| SHC68-C68-RDIO2 Cable | 156166-02 | NI | 2 meter |

| SH37F-37M-1 | 778621-01 | NI | 37-pin Female to Male Shielded I/O Cable, 1 meter |

| SH37F-37M-2 | 778621-02 | NI | 37-Pin Female to Male Shielded I/O Cable, 2 meter |

*See module user manuals for cable recommendations.

| Accessory | NI Part Number | Vendor | Description |

|---|---|---|---|

| Front Panel Filler Kit | 785206-01 | NI | 4 count |

| Rear Panel Filler Kit | 785207-01 | NI | 4 count |

| Filter Replacement Kit | 785208-01 | NI | N/A |

| Fan Replacement Kit | 785218-01 | NI | N/A |

| Power Connector | 785219-01 | NI | 5 count |

| RTI Strain Relief | 785999-01 | NI | 5 count |

While NI and our partners are developing and releasing modules we feel will be widely used, we know that there are specific requirements that are unique to your test system. To address these needs, our partners can design and deliver a test system based on NI’s platform that is tailored to your unique test demands.

An NI Partner is a business entity independent from NI and has no agency, partnership, or joint-venture relationship with NI.