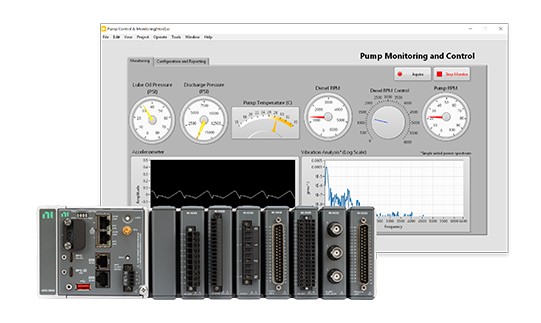

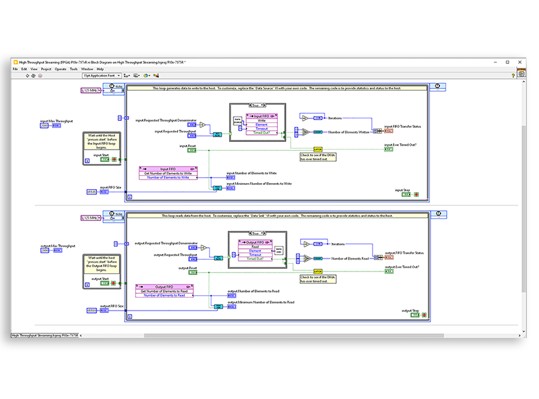

CompactRIO hardware provides an industrial control and monitoring solution using sensor- or protocol-specific, conditioned I/O modules with real-time capabilities.

Best for

Real-time processing needs

Industrial monitoring and control applications

Long-term testing in the field