Modal Analysis in LabVIEW

Contents

The past years have witnessed several severe bridge collapses around the world. These disastrous events have led to hundreds of lives and billions of dollars lost. Unfortunate accidents like these can be avoided in the future through better design, validation, and monitoring of critical structures such as bridges. For this reason, modal analysis has become increasingly popular in R&D and more importantly in online real-time monitoring systems. National Instruments continues to provide modal analysis solutions from laboratory test to online monitoring. This paper discusses in detail the hardware architecture as well as the specific modal parameter extraction algorithms used in industry to uncover the modal parameters of a structure.

Introduction

Modal analysis is the study of the dynamic properties of a structure under vibration excitation. Through modal analysis, structural engineers can extract a structure’s modal parameters (dynamic properties). The modal parameters, including natural frequency, damping ratio, and mode shape, are the fundamental elements that describe the movement and response of a structure to ambient excitation as well as forced excitation. Knowing these modal parameters helps structural engineers understand a structure’s response to ambient conditions as well as perform design validation.

Industry Trends

There are two types of modal analysis performed in industry today: experimental modal analysis and operational modal analysis. Experimental modal analysis is the most commonly used form of modal analysis today. It is the traditional method in which an individual uses a device, such as a hammer, to excite a structure and then measures the response. Then, the transfer function is calculated and certain modal parameter extraction algorithms are used to extract the dynamic properties of the structure.

Experimental modal analysis has been very useful in design validation and finite element analysis (FEA) verification; however, it has not proved useful in monitoring the long-term health of a large structure such as a bridge. For this reason, operational modal analysis has become the focus of innovation. Operational modal analysis is strictly concerned with the operation of a structure. This type of analysis focuses on monitoring the modal parameters of a structure and looking for trends in the data as warnings for failure. With operational modal analysis, structural engineers can proactively monitor the health of a bridge to avoid these catastrophic failures in the future.

Experimental Modal Analysis

Experimental modal analysis is the field of measuring and analyzing the dynamic response of a structure when excited by a stimulus. Experimental modal analysis is useful in verifying FEA results as well as determining the modal parameters of a structure. Performing experimental modal analysis is a four step process:

Figure 1: Experimental Modal Analysis Process

Vibration Sensors (Accelerometers)

Vibration sensors, known as accelerometers, must be properly placed on a structure to record the vibration response of a structure due to a known excitation by either a shaker system or an impulse hammer. These excitation systems are necessary to properly excite the modes of the system which reveal the modes of the structure. The accelerometers must have the frequency range, dynamic range, signal-to-noise ratio, and sensitivity needed for the specific test scenario. Vendors such as PCB Piezotronics work to ensure that the proper sensor is chosen for the application.

Figure 2: PCB Accelerometer for Measuring Vibration

Data Acquisition

Specialized data acquisition (DAQ) hardware is needed to properly acquire these vibration signals. The recommended data acquisition hardware is the NI Dynamic Signal Analyzer (DSA), which simultaneously acquires each channel with 24-bit high-resolution delta sigma ADCs. These DSA products have anti-aliasing filters to prevent aliasing and noise from affecting the measurement quality. Finally, they have the proper signal conditioning to power piezoelectric (ICP or IEPE) accelerometers. National Instruments has a variety of platforms available including USB, wireless 802.11g, PXI, and real-time embedded targets.

Figure 3: National Instruments DAQ Hardware

FRF Analysis

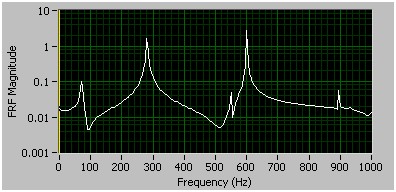

The frequency response function (FRF) compares the stimulus and response to calculate the transfer function of the structure. The result of the FRF is the structure’s magnitude and phase response over a defined frequency range. It shows critical frequencies of the structure, which are more sensitive to excitation. Those critical frequencies are the modes of the structure under test. An example of the magnitude result from an FRF is shown in Figure 4.

Figure 4: FRF Results for a Test Scenario

Modal Parameter Extraction

Modal parameter extraction algorithms are used to identify the modal parameters from the FRF data. These algorithms include peak picking, least square complex exponential (LSCE) fit, frequency domain polynomial (FDPI) fit, and FRF synthesis. Each of these algorithms perform the same function of identifying the modal parameters, however, each are optimized for a specific test scenario.

- Peak picking is a method used to extract a mode from a precomputed signal’s FRF. It is a frequency domain single-degree-of-freedom (SDOF) modal analysis method and suitable to estimate uncoupled and lightly damped modes. The computation is fast, but the result is sensitive to the frequency shift.

- LSCE fit is used to simultaneously extract multiple modes from precomputed signal’s FRF. It is a time domain multiple-degree-of-freedom (MDOF) modal analysis method and suitable for estimating modes in a wide frequency band. It is ideal for lightly damped modes.

- FDPI fit is used to simultaneously extract multiple modes from precomputed signal’s FRF. It is a frequency domain MDOF modal analysis method suitable to estimate heavily damped modes, particularly for heavily damped modes in a narrow frequency band.

- FRF synthesis is used to create synthetic FRF for testing and evaluation. With computed modal parameters, engineers can compare synthesized FRF and original FRF to verify the resulting estimation.

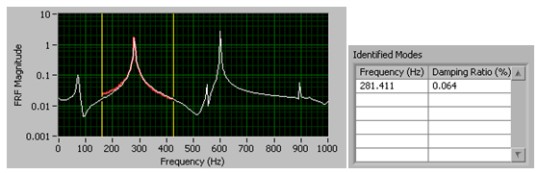

The end result of each algorithm is identified mode(s). As explained above, each algorithm is used in a certain scenario. As an example, in Figure 4 there is a peak around 280 Hz. If the user is interested in identifying that mode, FDPI fit is the correct choice because it is a narrow frequency band. The result of the FDPI algorithm is shown in Figure 5.

Figure 5: FDPI Fit Test Results

Operational Modal Analysis

With more and more focus on increasing safety, real-time structural monitoring systems have become a necessity to monitor the integrity of bridges and other structures. Operational modal analysis is a specific type of modal analysis primarily used in real-time structural monitoring systems. Operational modal analysis consists of specific algorithms to extract modal parameters from a structure in operation. The stimulus in operation is ambient conditions such as cars, wind, seismic activity, and so on. Because the stimulus is an unknown signal, specialized algorithms such as stochastic subspace identification (SSI) have been developed, which do not require knowledge of the stimulus, only the response.

Operational modal analysis is a three step process to extract the modal parameters:

Figure 6: Operational Modal Analysis Process

Vibration Sensors (Accelerometers)

Accelerometers are used just as discussed above in experimental modal analysis. Most of the requirements are the same including sensitivity, dynamic range, frequency range, and so on. However, there are a few more requirements including corrosion resistance, temperature change sensitivity, and cable length requirements. Each of these requirements is specified by the sensor vendor. Vendors such as PCB Piezotronics work to ensure that the proper sensor is chosen for the application.

Data Acquisition

Operational modal analysis has a lot of the same requirements as discussed above. They require the use of DSA hardware to achieve simultaneous 24-bit resolution acquisition and high dynamic range. The main differences are in the platform requirements:

- A real-time operating system is necessary for developing a deployed system to run embedded locally at the structure. National Instruments has two platforms, NI CompactRIO and PXI, which use a real-time operating system. These systems are capable of acquiring and analyzing the waveform vibration data locally and/or streaming the waveform to a remote PC. That means these systems can either, analyze the data locally and transmit only alarming conditions to an operator, or the systems can stream the vibration data from the structure to a remote operator for in-depth trending analysis.

- Distributed synchronization is necessary to achieve minimal phase mismatch. National Instruments continues to be a pioneer in the use of cabled and/or GPS technology for high-channel synchronization. National Instruments hardware is spec’d to within 0.1 degrees phase mismatch at 1 kHz within a single PXI chassis of up to 272 channels. With GPS technology, National Instruments has benchmarked the same 0.1 degrees phase mismatch on multiple chassis at 1 kHz.

An example application of a large real-time, synchronized structural monitoring system is the Donghai Bridge, the world’s largest bridge, which is located in the East China Sea. The Donghai Bridge is currently monitored 24/7 with National Instruments hardware consisting of 14 PXI systems running real-time operating systems and synchronized through GPS technology. This is shown in Figure 7.

Figure 7: Donghai Bridge Monitored by National Instruments Hardware

Modal Parameter Extraction

Modal parameter extraction is a bit more difficult in operational modal analysis because the stimulus is unknown. For that reason, the algorithms listed above (LSCE, FDPI, peak picking) are not applicable. Instead, a new algorithm is introduced called stochastic subspace identification (SSI). The SSI technique is used to simultaneously extract multiple modes from time data samples (as opposed to FRF data samples previously). It is a time domain MDOF operational modal analysis method.

Conclusion

NI is a hardware and software provider for performing both experimental and operational modal analysis. NI provides high-performance acquisition on platforms from USB and Wi-Fi 802.11g to embedded real-time targets. NI products are capable of simple, portable USB test acquisitions as well as large channel GPS synchronized online monitoring systems.