Advantages of NI Oscilloscopes

Contents

- Overview

- Synchronization and Integration for Mixed-Signal or High-Channel-Count Systems

- High Data Throughput

- Density

- Software-Designed Instruments

- Programming the Instrument

- Synchronization With NI-TClk

- Become More Productive With Oscilloscopes

- Take the Next Step

Overview

Traditional benchtop oscilloscopes are optimized to meet the needs of design engineers who primarily use the instrument interactively and prioritize features such as time to first measurement, waveform visualization, and connectivity to a wide array of probes. Although newer box oscilloscopes improve on this experience by adding features such as higher bandwidth and turnkey software for analyzing bus protocols, they often fail to address the needs of engineers building automated test systems or high-channel-count, high-speed measurement systems. These engineers need to acquire and analyze a large set of data in an automated fashion, and typically prioritize things such as integration with other instruments, size, programming experience, and data throughput or execution time. Because of these unique needs, many of these users are moving toward a modular platform that provides the measurement performance of traditional box oscilloscopes in a form factor that is optimized for their application.

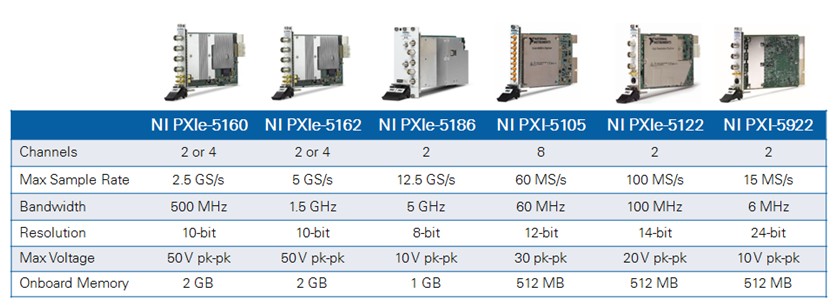

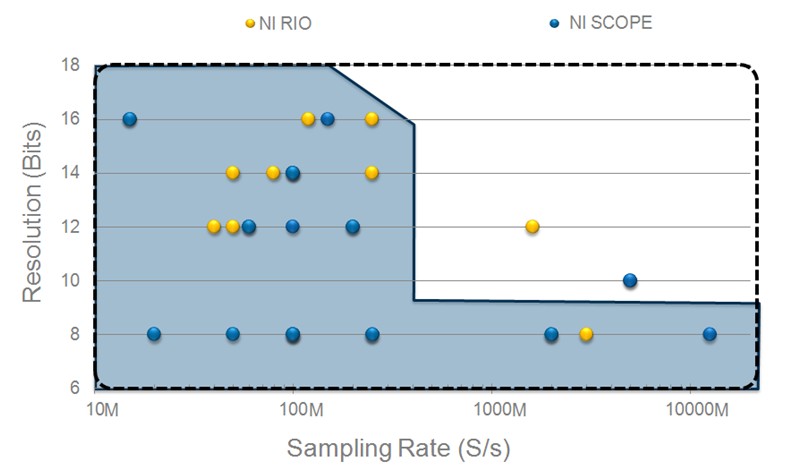

NI provides the widest range of modular oscilloscopes in the PXI platform, so you can optimize your system for cost, density, measurement resolution, or sampling rate. Figure 1 below plots the sampling rate and resolution of various NI oscilloscopes. The blue I/O points represent software-defined oscilloscopes that are programmed using the NI-SCOPE instrument driver, while the yellow I/O points represent FPGA-based digitizers that use the NI reconfigurable I/O (RIO) architecture.

Figure 2 details some of the oscilloscope specifications called out in the blue I/O points above. These oscilloscopes provide the measurement capability users expect from a traditional instrument, such as selectable input ranges, input coupling and impedance, filters, and traceable calibration. They also support soft front panels and are programmed with instrument drivers that include prebuilt functions for performing standard oscilloscope measurements such as rise time, frequency, and pulse width or define the functionality through software.

Figure 2. Choose from an extensive portfolio of oscilloscopes.

The FPGA-based digitizers detailed in the yellow I/O points of Figure 1 pair high-speed sampling with a user-accessible FPGA that makes them ideal for onboard signal processing, real-time analysis, or custom trigger implementation.

Figure 3. Define the I/O needed for your application by changing the adapter module.

NI has a broad range of PXI oscilloscopes and FPGA-based digitizers that are designed for high-channel-count or mixed-signal automated test systems. Even though the specs vary from high resolution to high speed, NI oscilloscopes share several key attributes that optimize them for these applications, including:

- Tight integration and synchronization with other instruments

- The ability to store and stream large amounts of data

- High channel density

- Custom triggering and onboard signal processing

- A comprehensive software experience for quickly taking measurements, programming, and debugging

Synchronization and Integration for Mixed-Signal or High-Channel-Count Systems

Mixed-signal test systems are composed of many types of instruments such as signal sources, measurement devices, and switches. NI PXI oscilloscopes provide tight integration and synchronization with other instruments by pairing PXI platform advantages with patented NI technology. With a PXI system and NI modular instrumentation, you can not only build a comprehensive test system in a single, compact PXI chassis, but also ensure measurement quality and repeatability because modules in the chassis can be synchronized with picosecond-level accuracy.

Figure 4. A wide variety of modular instruments are available in the PXI platform.

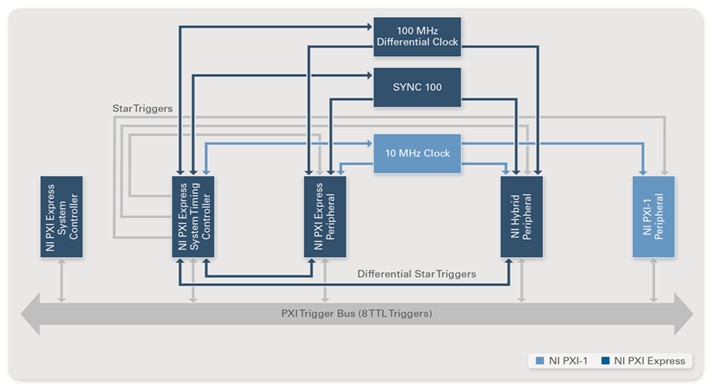

Through synchronization, you can match the timebase and triggering of several instruments of the same type for channel expansion purposes, or tightly correlate the inputs and outputs of different instruments. Basic methods of synchronization involve sharing triggers and sample clocks, while more advanced synchronization involves aligning multiple sample clocks of varying speeds and adjusting for phase delays between clocks and triggers. The PXI architecture addresses some of these challenges by evenly distributing triggers and sample clocks via the backplane of the PXI chassis, as shown in Figure 5.

Figure 5. The PXI Express backplane simplifies timing and synchronization.

Additionally, NI oscilloscopes share a common Synchronization and Memory Core (SMC) technology with other instruments such as signal generators and high-speed digital I/O. This patented technology uses a separate clock domain signal to enable the driving and receiving of triggers between different instruments, and results in synchronization in the 10s of picoseconds. This trigger, called the Trigger Clock (TClk), results in significantly better performance than locking the sample clock to the 10 MHz reference clock only.

High Data Throughput

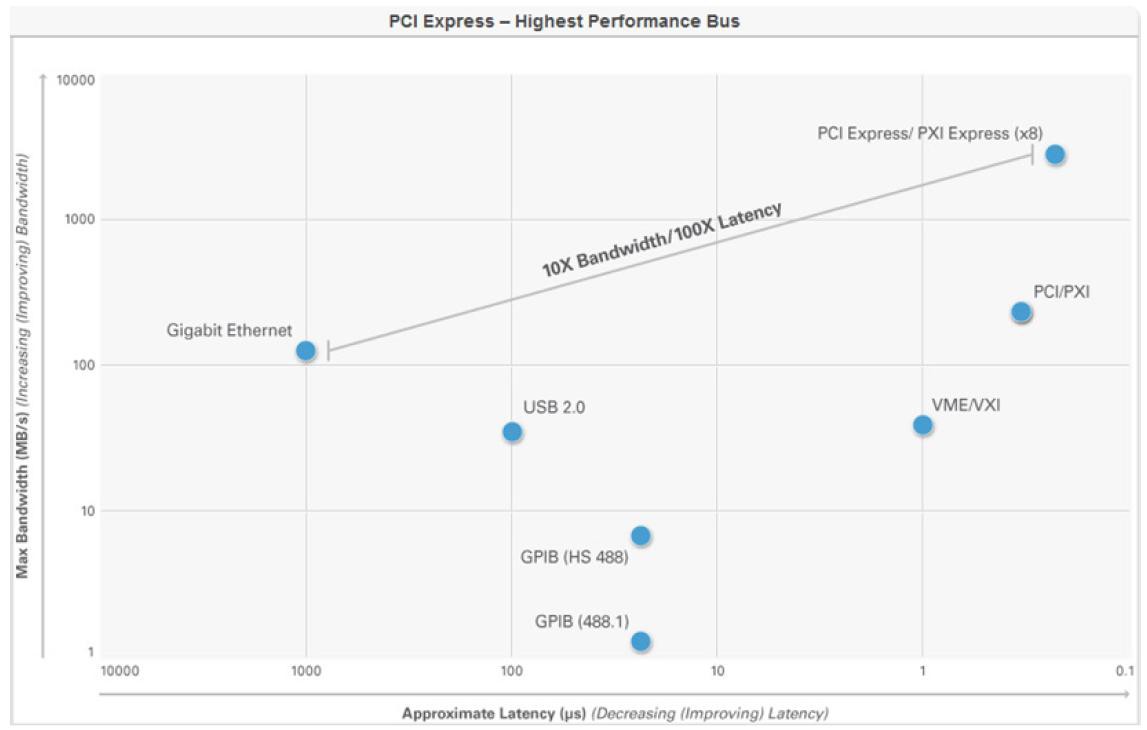

Companies incur a variety of expenses related to efficiently and accurately testing products. In addition to the initial test equipment expenditures, factors such as test time greatly influence your cost of test. Although every application is unique and has specific needs, automated test systems always have some commonality. Bandwidth and latency are two of the most important considerations for an automated test system, because the combination of the two dictates the overall speed of your measurement system.

Figure 6. Bus bandwidth and latency of popular instrumentation buses.

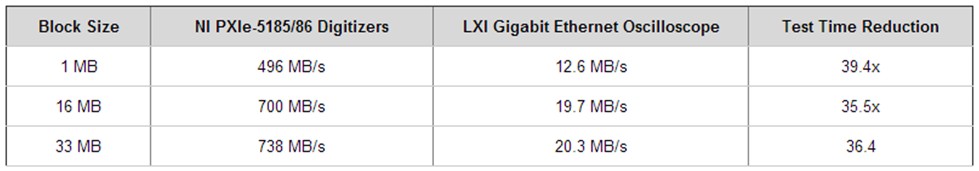

Latency describes the amount of time it takes for an instrument to respond to a remote command, like a measurement query. Bandwidth refers primarily to the data throughput capacity of data bus that connects the measurement instrument with the host PC or controller. A high-bandwidth bus results in lower test times, no matter if the application is to transfer a large data record one time or transfer small data records multiple times in a row. The PXI platform—upon which NI high-speed oscilloscopes are built—provides high speed for a wide range of applications with both high bandwidth and low latency via the PCI and PCI Express buses. PXI Express, a version of PXI that uses the high-speed PCI Express bus, achieves system throughput rates of several GB/s, depending on the chassis and controller. Both PXI and PXI Express data throughput rates are significantly faster than that of GPIB, USB, or LAN—other popular buses for automating test instrumentation (Table 1).

Table 1. Compare data throughput rates for PXI and Ethernet.

Density

NI PXI oscilloscopes are more compact than traditional benchtop instruments, which means you can build mixed-signal automated test systems at a fraction of the size of rack-and-stack testers. A small footprint test system saves valuable space on production floors and characterization labs, increases portability by reducing the weight and size, and often results in reduced facilities’ costs and test infrastructure as power distribution and cooling requirements are reduced.

Figure 7. Combine NI oscilloscopes with other instruments to create compact automated test systems.

Oscilloscope channel density is especially important when acquiring data from more than four channels simultaneously, as most traditional box oscilloscopes max at four channels. Because box oscilloscopes are optimized for low-channel-count benchtop applications, they have many physical knobs and large displays for acquiring and displaying data. The physical space occupied by the front panels of these instruments makes them impractical to stack together for high-channel-count systems.

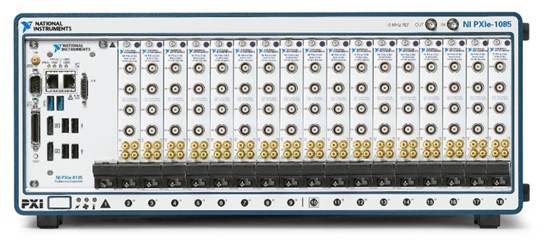

PXI oscilloscopes remove many of the redundancies, such as individual displays, physical knobs, power supplies, and fans, associated with traditional instruments. The PXI chassis and controller handle the processing, data transfer, cooling, and supply power to the instruments, while the user controls the instrument via software and displays data on a single monitor. Using the PXI platform and NI oscilloscopes, you can build high-channel-count systems with up to 136 channels in a single 4U, 19 in. PXI chassis.

Figure 8. Combine up to 68 or 136 oscilloscope channels in a single PXI chassis (19 in., 4U rack) for high-speed acquisition systems.

Software-Designed Instruments

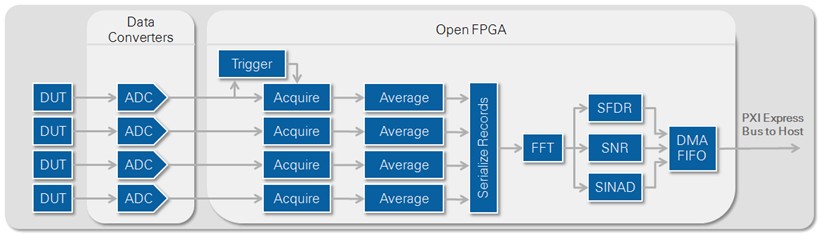

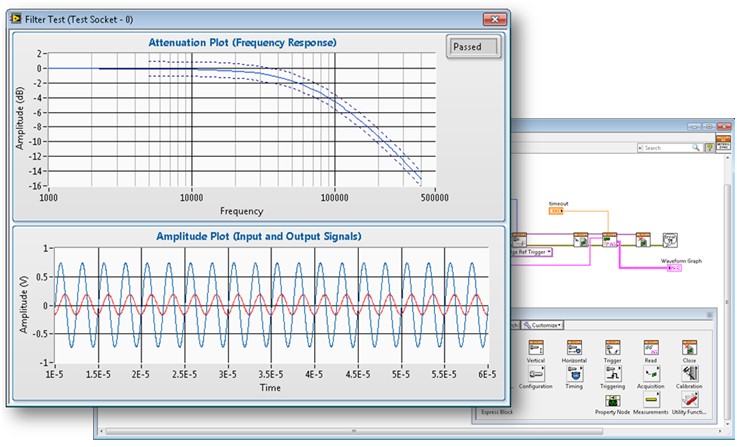

Most test instruments today incorporate FPGAs with fixed firmware to implement the capabilities of the instrument. The software-designed oscilloscopes by NI feature an open FPGA that gives users the ability to perform complex algorithms on the instrument, significantly reducing the amount of data that needs to be streamed to the host. This example shows how to architect an application that can perform common calculations, namely SFDR, SNR, and SINAD, on the FPGA of the instrument.

Figure 9. This open FPGA block diagram illustrates the architecture to calculate SFDR, SNR, and SINAD on the FPGA.

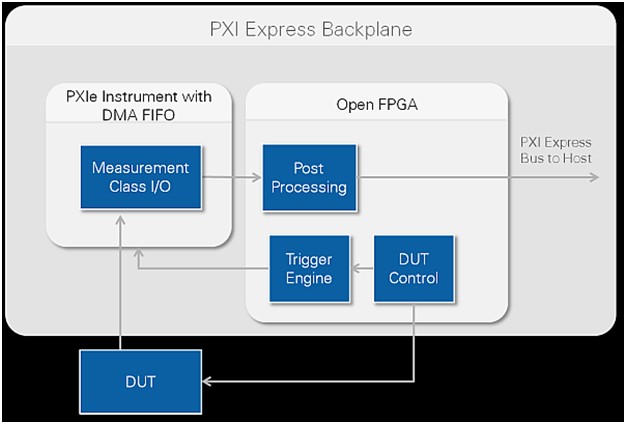

The high data throughput topic in the previous section refers to both increased bandwidth and decreased latency. These benefits are greatly increased with the use of the open FPGA architecture as defined by the software-designed oscilloscopes. A unique feature of NI FlexRIO FPGA modules for PXI Express is that they can stream data between modules at rates of 3 GB/s without routing data through the host chipset. Up to 16 such streams are supported, simplifying complex multi-FPGA communication schemes without taxing host CPU resources. For more information on this technology, refer to the white paper titled An Introduction to Peer-to-Peer Data Streaming.

Figure 10. In a test instrument, an open FPGA can add features such as triggering and post-processing.

Programming the Instrument

One of the most commonly overlooked features of an oscilloscope is the software used to control and program the device for automated test and measurement. Unfortunately, this can be a crucial oversight, as software plays heavily into the application development time. NI oscilloscopes provide a variety of software tools to accelerate productivity by giving you the ability to quickly acquire data, debug applications, automate your data acquisition, and synchronize with other instruments.

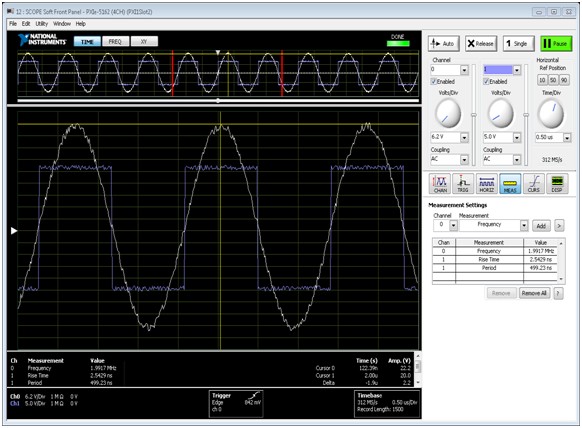

Getting Started With the NI-SCOPE Soft Front Panel

This interactive program resembles the dedicated display of a traditional oscilloscope to provide an easy-to-use interface. Along with providing access to the basic functionality of all NI oscilloscopes, it provides real-time measurements as well as the ability to save data to a file for post-processing and analysis. This interface makes it easy to begin taking measurements with an NI oscilloscope in seconds.

Figure 11. Quickly take a measurement using the NI-SCOPE soft front panel.

Programming With the NI-SCOPE Driver and Example Programs

To take advantage of the full power of a PC-based measurement device, it is essential to programmatically define and control its behavior. All NI oscilloscopes can be programmatically controlled via the NI-SCOPE instrument driver, which provides both high-level functions for getting started quickly, as well as low-level control for accessing all the features of an oscilloscope. In addition, this driver includes more than 50 prewritten example programs that illustrate how to access the full functionality of any NI oscilloscope. The NI-SCOPE instrument driver can be accessed through a variety of programming languages such as G in LabVIEW, C++, and Visual Basic. Programming examples exist for each.

Figure 12. Program with the NI-SCOPE driver to create a custom program.

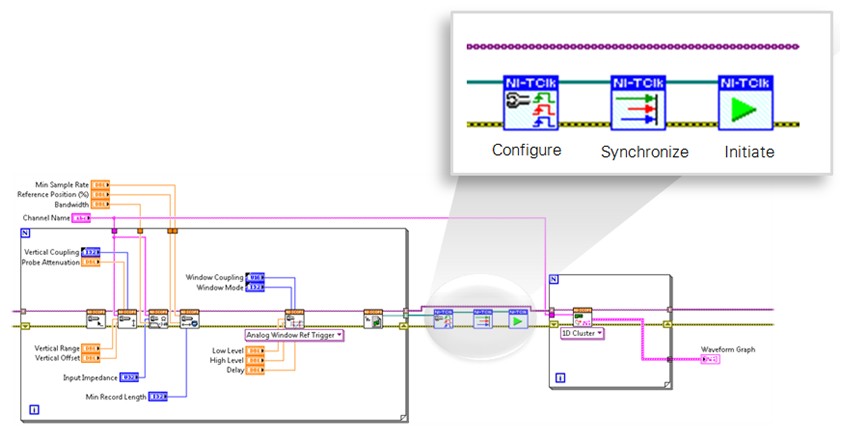

Synchronization With NI-TClk

Synchronization of multiple devices is a key requirement of many applications, which can often add to software development time. NI oscilloscopes that are built on the SMC architecture, however, can make use of NI-TClk to achieve precise synchronization with minimal development effort. NI-TClk provides a high-level interface for programming the synchronization of multiple NI oscilloscopes, arbitrary waveform generators, and high-speed digital I/O devices. Furthermore, a variety of prewritten examples can perform this type of synchronization, which makes getting up and running even easier. Shown below are the three functions needed to perform homogenous synchronization on multiple PXI oscilloscopes as programmed in the LabVIEW environment.

Figure 13. Synchronize NI oscilloscopes using three functions in LabVIEW or LabWindows™/CVI.

Become More Productive With Oscilloscopes

NI oscilloscopes provide the measurement performance of traditional box oscilloscopes in a form factor optimized for automated test and high-channel-count applications. With a range of PXI-based oscilloscopes and FPGA-based digitizers, you can optimize your system for density, resolution, bandwidth, and sampling rate. Additionally, software-designed instruments provide an unmatched level of flexibility by giving you the ability to customize the instrument using the LabVIEW FPGA Module. From providing out-of-the-box software tools for quickly taking measurements and debugging applications to building fully automated test programs and implementing custom algorithms on the hardware, NI oscilloscopes provide the best hardware and software combination to make you more productive in building automated test and high-channel-count systems.

Take the Next Step

- Explore the complete portfolio of oscilloscope instruments

- Configure a PXI system today through an online advisor

- Learn the fundamentals of building a test system

The mark LabWindows is used under a license from Microsoft Corporation. Windows is a registered trademark of Microsoft Corporation in the United States and other countries.