Products to Engineer the Future

NI offers modular hardware, software, services, and systems that set the standard for automated test and measurement systems. Let's find the right products to help you test faster, design better, improve reliability, and maximize your test data.

Systems that scale

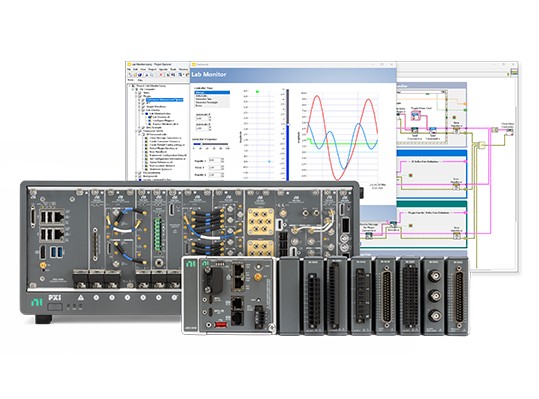

Systems include modular hardware across unifying form factors with interoperable software products. For turnkey solutions, NI offers application-specific systems with customized functionality. Let’s tailor a system that meets your unique requirements.

Key System Components

Chassis

As the backbone of a system, the chassis provides power, cooling, and a communication bus to the system, and supports multiple modules or instruments.

Controller

Integrated or external, the controller contains everything you need to run your system.

Modules

Each module’s individual functions and I/O help the overall system fulfill its requirements.

Software

NI software helps you customize and reconfigure systems to solve test requirements that evolve over time.

Services

NI’s consulting, integration, hardware, and software services ensure your success.

Chassis

As the backbone of a system, the chassis provides power, cooling, and a communication bus to the system, and supports multiple modules or instruments.

Controller

Integrated or external, the controller contains everything you need to run your system.

Modules

Each module’s individual functions and I/O help the overall system fulfill its requirements.

Software

NI software helps you customize and reconfigure systems to solve test requirements that evolve over time.

Services

NI’s consulting, integration, hardware, and software services ensure your success.

Product Bundles

CompactDAQ Measurement Bundles

CompactDAQ measurement bundles are preconfigured sets of NI’s most popular, high-quality data acquisition hardware.

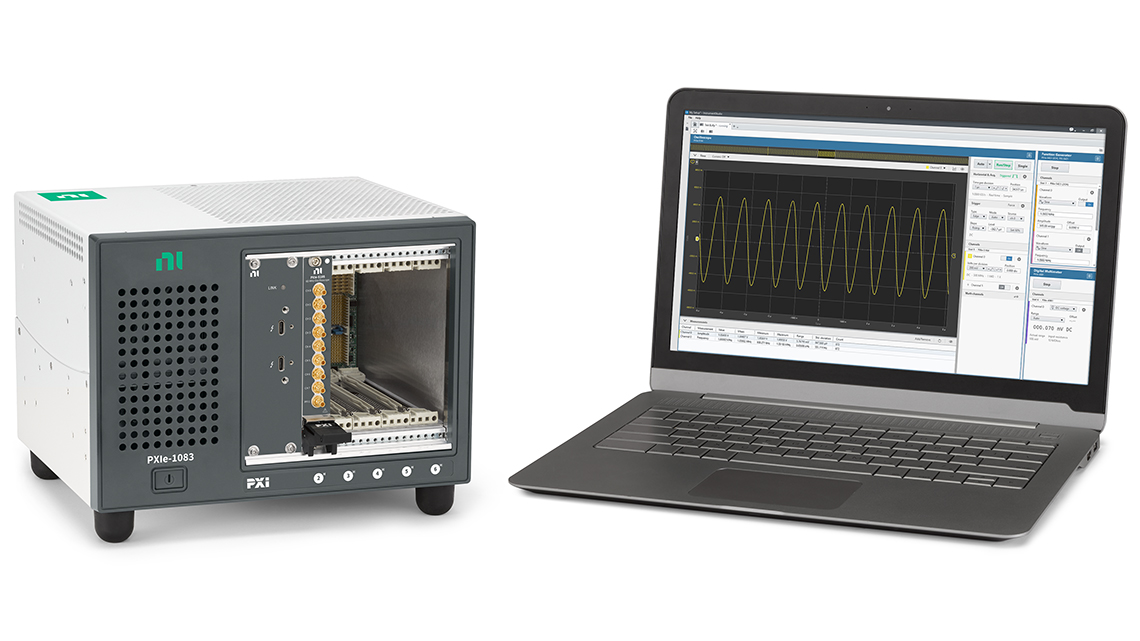

PXI Instrument Bundles

PXI Instrument bundles are preconfigured sets of NI’s most popular, high-quality electronic test and instrumentation hardware.