- Confidently meet your test milestones, launch dates, and quality KPIs.

- Achieve leaner maintenance, training, and deployment operations.

- Maximize your test throughput.

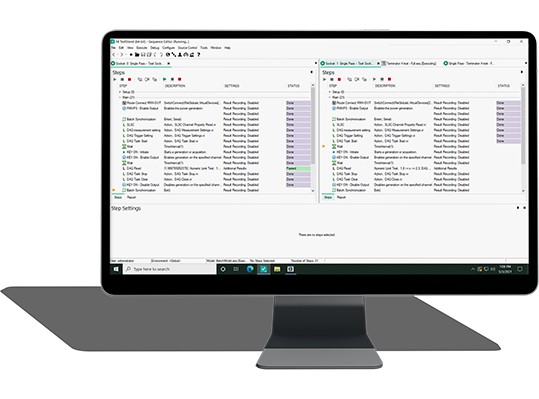

- Simplify your test development work.

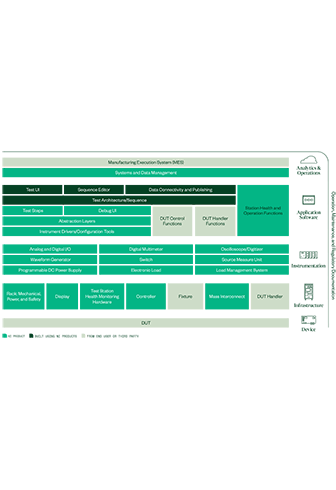

- Ensure successful standardization and lean manufacturing.