OSL Creates Universal Automated Test System for Satellite Payload Power Supply

Ishan Patel, System Engineering Lead, Optimized Solutions Limited (OSL)

Sintu Punnoose, Senior Applications Engineer, NI

Case Study Highlights

OSL innovates in the Indian space industry by delivering automated systems (ATS) that test different power-rated DC-DC converters and reduce test time 10X compared with traditional approaches.

As the core element of the ATS, NI’s modular PXI Express system controls power supplies and electronic loads, acquires test data, and analyzes data to evaluate DUT performance.

OSL’s ATS solution meets requirements of both card- and package-level testing, including support for testing multiple devices under test (DUTs) simultaneously with different tuning algorithms.

“Leveraging the NI PXI platform, we’ve built a satellite payload power supply system that reduces test time by 10X and supports both board- and package-level testing. OSL’s solution will be leveraged by the Indian space community to enable scalability through automation and increase the pace of innovation.”

—Harikesh Nair, Executive Director, Optimized Solutions Limited (OSL)

The Challenge

Tuning, testing, and validating a satellite payload power supply requires the characterization of DC-DC converter electrical parameters. Different power-rated DUTs with multiple specifications must be tested to ensure regulated power reaches all subsystems. Traditional methodologies can take up to seven days to tune a DUT; test results are captured manually, which can result in overall test time exceeding one month.

The Solution

OSL’s solution tests two DC-DC converter DUTs simultaneously by incorporating 20 different critical electrical parametric tests, such as isolation and stability tests. The ATS has a single 19-inch rack with multiple NI PXI instruments along with a LabVIEW-based test application. The solution increases the throughput of the system, minimizes the risk of human error, and ultimately reduces test time by 10X compared to traditional methods.

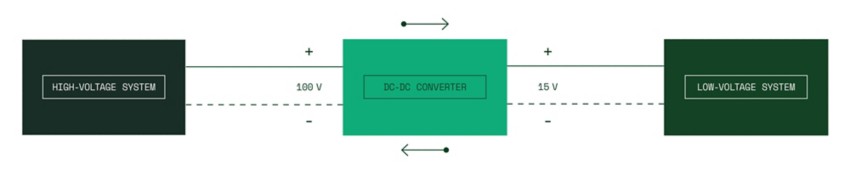

DC-DC Converter Basics

A DC-DC converter is an electrical device which converts direct current (DC) sources from one voltage level to another. In other words, a DC-DC converter takes a DC input voltage and outputs a different DC voltage. Power management systems like DC-DC converters manage or convert power within larger systems, like those found in satellite payloads, for applications such as upconverting or downconverting a source of direct current from one voltage level to another.

Figure 1: DC-DC Converter Block Diagram

DC-DC Converter Requirements

Whether performing design validation prior to manufacturing or evaluating a DC-DC converter for possible use in a satellite payload system, the need for repeatable and precise testing is essential. Standard DC-DC converter test sequences measure performance criteria such as voltage accuracy, efficiency, line/load regulation, and transient response.

Hundreds of DC-DC converters with different specifications are designed and deployed. The DC-DC converter, which in this case is the DUT, must go through different phases including fabrication, component tuning, testing, and validation—and in many cases the most time-consuming phase is component tuning and testing.

In tuning, multiple resistors and capacitors must be emulated to check the DUT performance. In traditional test setups, these values are changed manually each time. After tuning, DUT performance is evaluated to verify the output values remain within requirement thresholds. Multiple tests must be performed with different instruments in different test setups, and test results are typically captured manually. Additionally, the DUT must be tested in different environmental conditions. Overall, to complete the DUT performance test through all phases, this process typically takes at least one month.

Solution

Optimized Solutions (OSL) is an NI Partner and a leading product engineering service provider for build to specifications, embedded firmware, and entire product development lifecycle management services. Founded in 2005 and located in the Indian state of Gujarat, OSL has a Pan-India presence supported by more than 100 engineers. OSL provides high-quality solutions and services to space, defense, and OEM industries.

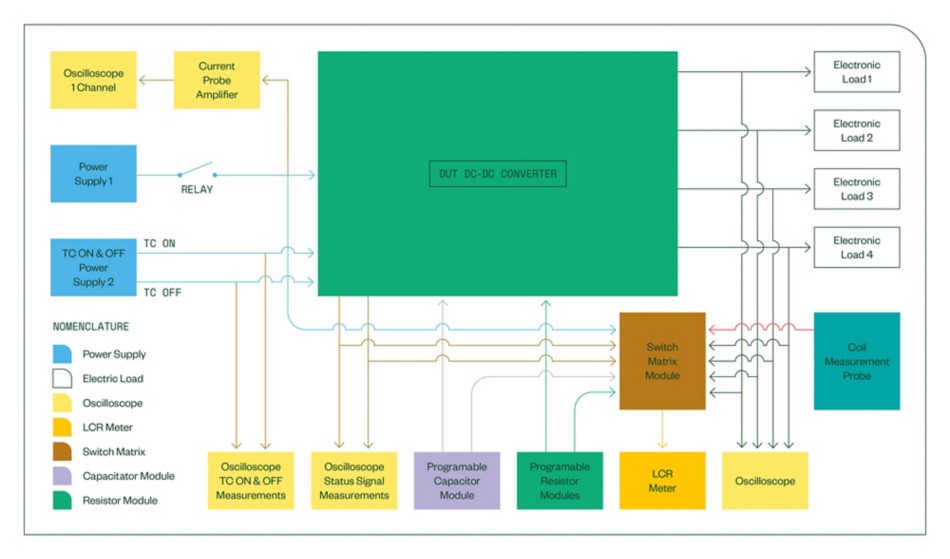

This solution is built on the NI PXI Express platform for card-level tuning and testing (T&T) and testing and evaluation (T&E) activities for different types of DC-DC converters. The solution meets customer requirements to increase throughput as well as minimize manual efforts and human errors in testing. It also addresses the need for automating the T&T process in all phases of DC-DC converter DUTs. The NI PXI Express system controls the instruments through test application software developed using LabVIEW. The solution is customized to meet specific requirements and allows for testing of two DUTs simultaneously with different tuning algorithms in a single ATS.

Figure 2: System Architecture

The NI PXI Express system controls the required power supplies, electronic loads, and other modular measurement equipment. In addition, it acquires the test data and analyzes the data to evaluate the DUT performance. The solution is configured in an easily transportable rack to enable its use across locations. The following NI PXI hardware is used for the ATE solution:

- PXIe-1095 and PXIe-1092 PXI Chassis

- PXIe-8880 and PXIe-8840 Controller with Windows 10

- Power supplies:

- RMX-4104 Power Supply (100 V, 8 A)

- RMX-4003 High-Power Electronic Load (100 W)

- PXIe-4139 Low-Power Electronic Load (40 W)

- PXI-2532B Matrix Switch Module

- PXIe-4082 Digital Multimeter

- PXIe-5172 14-bit Oscilloscope

- PXIe-4137 Source Measure Unit

- PXIe-6365 Multifunction I/O Module

- PXI Digital I/O Module

- PXIe-8431/8 Serial Interface Module

Customized Solution

All the previously mentioned modular instruments are placed inside a 19-inch rack. A single connector on both side walls of the ATS connects to the DUT using a mounting stand inside the rack, which is tailored to the specific DUT design shared by the customer.

The requirement to test the DUT in various environmental conditions encouraged the team to adapt the movable rack design for easy transportability.

Key Software Features

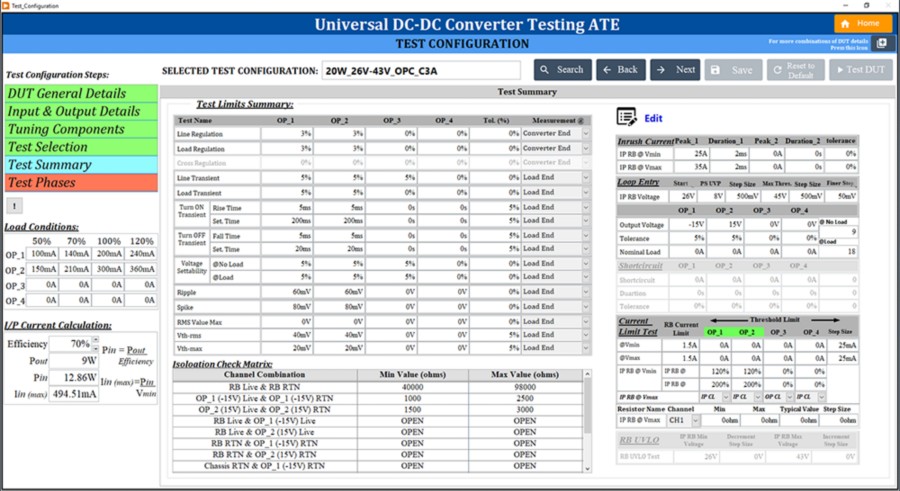

The Test Configuration Module offers the following benefits:

- Support for testing different types of DUTs

- Multiple configuration storage for different DUTs

- Capability to edit the stored configuration and save it for different types of DUTs

- User configurable tunable components with limits available in test configuration

- User selectable test sequences

- User defined test sequences for different test phases

Figure 3: Test Configuration Module

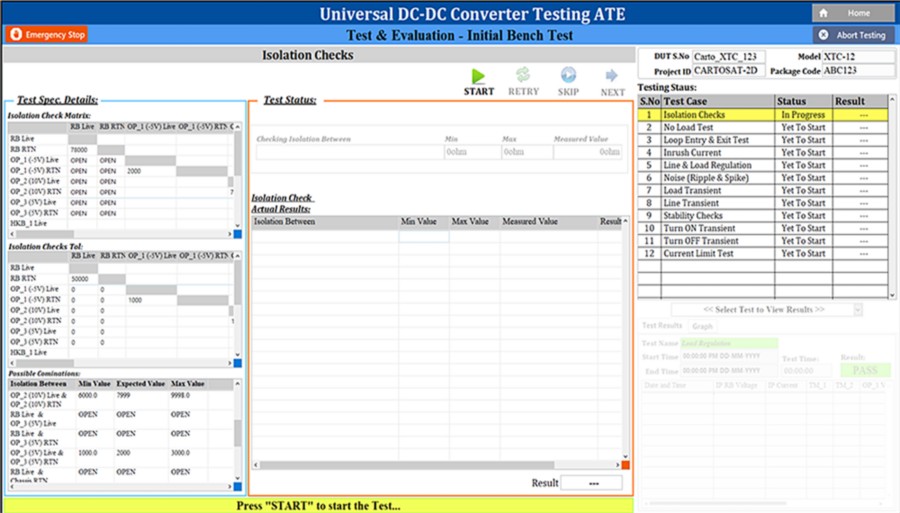

The Testing Module offers the following benefits:

- Includes barcode scanner for the DUT

- Based on barcode, displays DUT details with all test parameters fetched from database and displayed in GUI

- Based on selected test phase, test application determines to proceed with tuning or testing

- Instrument health verification carried out before proceeding with the test

- All tests executed in defined sequence and customized report generated after testing is complete

Figure 4: Testing Module UI

Key Features and Benefits of the Solution:

- Automated RC component tuning

- Test configuration reusability for different types of DUTs

- Test sequence customization per user need

- Test case selection for different testing phases

- Instrument health check verification as a precheck, before proceeding to testing

- Multiple safety features to protect the DUT in case of inadvertent operation/condition

- Automated stability analysis using fast Fourier transform

- Automated test report generation after test completion

- Quick retrieval of DUT test results

- Test result comparison of different phases of the DUT

- Automated test results backup to server

With this ATS solution, the DUT performance testing time has been reduced by 10X, compared with manual testing. Additionally, DUT test results are more consistent and standardized through improved automation.

Summary

With this universal DC-DC converter automated test solution, enabled by NI’s modular architecture and flexible development tools, OSL delivers the desired capabilities for satellite payload package testing to Indian Space users to test DC-DC converter DUTs quickly. The solution can adapt to different test cases with agility and flexibility, enabling scalability and efficiency by automating reports. With this solution, test time can be reduced by 10X as compared to manual testing, with improved post-processing analysis and standardization of the DUT test results.

An NI Partner is a business entity independent from NI and has no agency or joint-venture relationship and does not form part of any business associations with NI.