Academic and Research

Whether in the classroom or the lab, today's students and researchers are looking to increase their rate of discovery and build solutions faster.

Research and Teaching Applications

Accelerate Discovery with NI Solutions

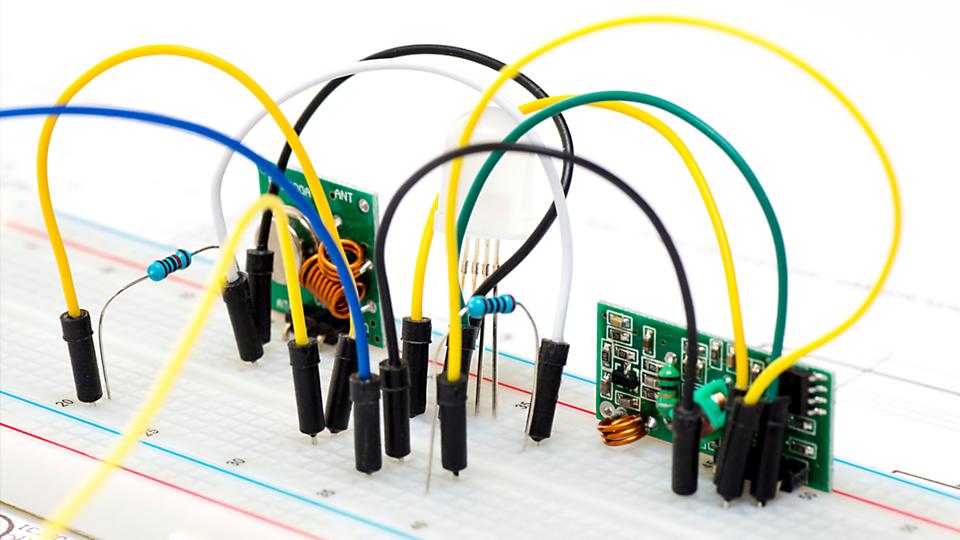

In today’s laboratories, lecture halls and dorm rooms, time to understanding and discovery has never been more critical. Researchers use the NI platform to push the boundaries of discovery. They are driven by the grand challenges humanity faces and the economic and technical trends that are revolutionizing wireless communications, transportation, and energy. Engineering educators are preparing students to become the innovators of tomorrow. This requires engaging, hands-on curriculum that inspires students and puts theory into practice. NI partners with education experts to develop the right tools to help students understand problems and build real solutions faster than ever. Take NI hardware and software into the lab or classroom to accelerate discovery.

Featured Content

Courseware Portal

Engineering Teaching Resources

Implement a hands-on approach to engineering education with resources developed by leaders in education. Browse our portal to find open-ended projects and ABET-aligned teaching resources to accelerate student discovery in key topics and application areas.

Engineering Education Solutions

Select from student devices or experiment-ready lab stations, and learn about hardware and software options for students, educators, and researchers.

Customer Success Story

See how Oklahoma State University created a studio learning environment where students can work with industry standard tools and achieve a deeper understanding of engineering concepts.

You can access the latest testing technology—including hardware and software—by renting equipment from Electro Rent, the authorized rental partner of NI in the U.S. and Canada.