Choosing the Right Hardware for Your Vision Applications

Overview

National Instruments offers a range of hardware options that support image acquisition and processing. In this document, explore how to choose among these different form factors by learning about the software support and camera support for each of these hardware platforms. Also see how these hardware options rate against different performance, industrialness, and integration criteria.

Contents

- NI Hardware Platform Options for Vision Applications

- Software and OS Support

- Comparison of Benefits and Features for Each Platform

- Camera Support and Camera Choice

NI Hardware Platform Options for Vision Applications

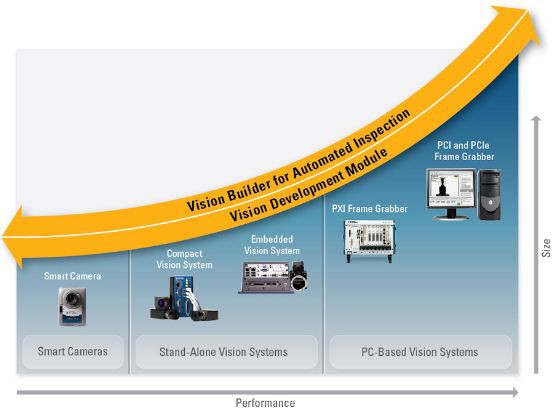

NI vision hardware offerings include a range of form factors from smart cameras to stand-alone vision systems to powerful PXI and PC-based solutions. These hardware platforms differ in several ways, including form factor and performance, and each are suitable for different environments, applications, and system architectures.

Figure 1. Primary Vision Hardware Platforms Offered by National Instruments

The highest-performance NI CompactRIO and NI Single-Board RIO controllers also support image acquisition and processing at lower bandwidths. This is achieved through smaller image resolution, lower speed, and more image compression than featured in other vision platforms.

Figure 2. CompactRIO and NI Single-Board RIO as a Vision Platform

Software and OS Support

NI vision software packages are designed to run with the hardware options presented in Figure 1. This means you can switch between platforms and even reuse large portions of existing code on any of the vision hardware targets. You can also reduce development time and maintenance costs associated with multiple systems by maintaining a single software package.

CompactRIO and NI Single-Board RIO platforms support only the NI Vision Development Module image processing libraries and not NI Vision Builder for Automated Inspection.

| Smart Camera | Compact Vision System | Embedded Vision System | PXI and PXI Express Systems | Industrial and Desktop PCs | CompactRIO/ Single-Board RIO | |

| Vision Builder for Automated Inspection | • | • | • | • | • | X |

| Vision Development Module | • | • | • | • | • | • |

Table 1. Vision Software Support for Hardware System Options

In addition to using the NI LabVIEW graphical programming environment on all the platforms, you can take advantage of the NI Vision Development Module to program systems running a Windows OS (see Table 2) from a text-based development environment using C, C++, Visual Basic, and .NET languages (Visual Basic .NET and C#).

| Smart Camera | Compact Vision System | Embedded Vision System | PXI and PXI Express Systems | Industrial and Desktop PCs | CompactRIO/ Single-Board RIO | |

| Windows | X | X | • | • | • | X |

| Real-Time | • | • | • | • | • | • |

Table 2. Operating System Support for Hardware System Options

Comparison of Benefits and Features for Each Platform

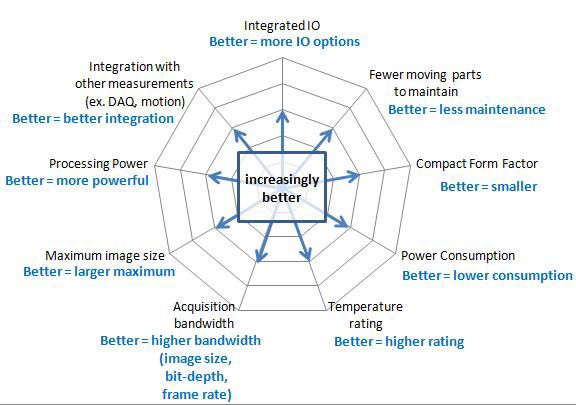

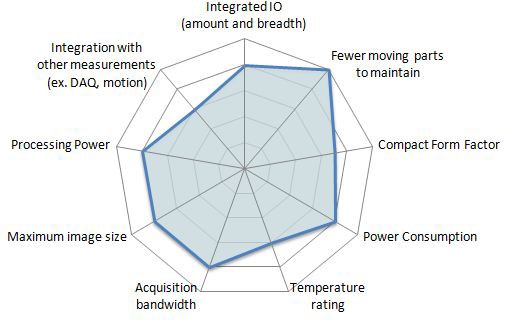

The different platforms are compared based on the following nine criteria:

- Integrated I/O – the amount of I/O as well as the breadth (digital TTL, digital optoisolated, analog)

- Fewer moving parts to maintain – fanless designs and solid-state drives are less susceptible to damage from vibration

- Compact form factor – smaller size and fit can be physically designed into larger systems

- Power consumption – total power drawn by system

- Temperature rating – range of temperature system for which system has been validated

- Acquisition bandwidth – maximum throughput at which images can be acquired into the system as defined by the combination of image resolution, bit depth, and frame rate

- Maximum image size – maximum image size that can be acquired on the system with memory and processing limitations

- Processing power – higher processing power is characterized by speed and number of cores or coprocessors

- Integration with other measurements (for example, DAQ, motion) – direct RTSI connection and triggering and availability of other modules that can be placed into system (C Series modules, PXI modules, PCI boards) compared to integration through Ethernet connections to other devices

Figure 3. Reference Radar Diagram

The distribution of how well each hardware platform rates is spread differently across the criteria in the radar diagram. Interestingly, the area covered is approximately the same in each diagram, which can also be seen in the similar total scores in the Table 3.

| Smart Camera | Compact Vision System | Embedded Vision System | PXI and PXI Express Systems | Industrial PCs and Desktops | CompactRIO/ Single-Board RIO | ||

| Industrial Suitability | Integrated IO (amount and breadth) | 3 | 4 | 4 | 5 | 5 | 5 |

| Fewer moving parts to maintain | 5 | 5 | 5 | 3 | 3 | 5 | |

| Compact form factor | 5 | 4 | 3.5 | 2 | 2 | 4 | |

| Power consumption | 5 | 4 | 4 | 2 | 2 | 5 | |

| Temperature rating | 4 | 4 | 3 | 4 | 3 | 5 | |

| Performance | Acquisition bandwidth | 3 | 3 | 4 | 4 | 5 | 1 |

| Maximum image size | 2 | 3 | 4 | 4 | 5 | 1 | |

| Processing power | 2.5 | 3 | 4 | 4.5 | 5 | 2 | |

| Integration with other measurements (for example, DAQ, motion) | 2 | 2 | 3 | 5 | 4 | 4 | |

| TOTAL | 31.5 | 32 | 34.5 | 33.5 | 34 | 32 | |

Table 3. Comparison of Ratings for All NI Vision Hardware Platforms

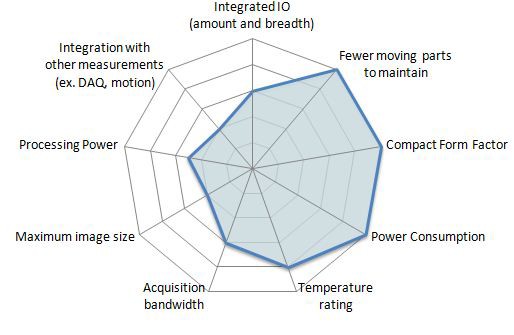

NI Smart Cameras

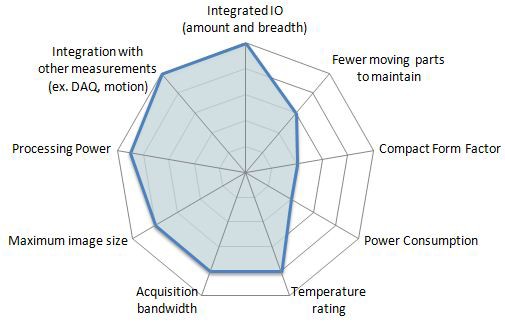

Figure 4. Radar Diagram for NI Smart Cameras

Features

- Integrated processor and image sensor

- Lowest power consumption

- Dedicated vision hardware

- DSP coprocessor on certain models for faster algorithm performance

- Integrated digital I/O and built-in lighting control

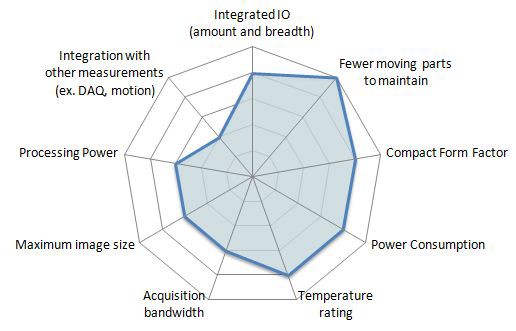

NI Compact Vision Systems

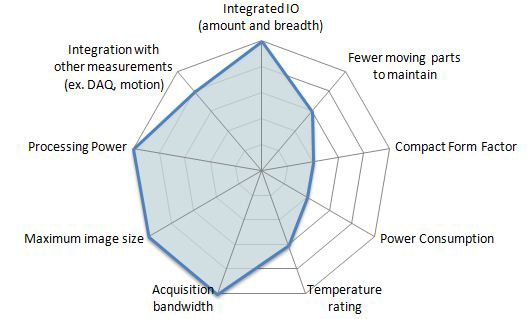

Figure 5. Radar Diagram for NI Compact Vision Systems

Features

- Multiple tethered IEEE 1394 cameras

(cheaper than smart cameras for multicamera systems) - Dedicated vision hardware

- Solid-state storage

- 29 reconfigurable digital I/O lines

- Most compact tethered system

NI Embedded Vision Systems

Figure 6. Radar Diagram for NI Embedded Vision Systems

Features

- Multiple tethered IEEE 1394 cameras

(cheaper than smart cameras for multicamera systems) - Dedicated vision hardware

- Dual-core processor and 2 GB RAM

- Fanless design and solid-state storage

- Many industrial communication and I/O options

PXI and PXI Express Systems

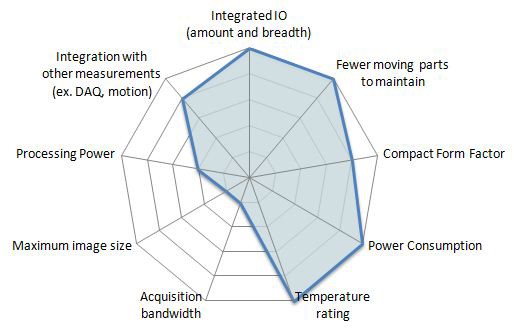

Figure 7. Radar Diagram for PXI and PXI Express Systems

Features

- Support for all imaging standards

- Unsurpassed timing, triggering, and integration with a star trigger, which is a high-performance trigger signal that can be used to synchronize all of the modules in a PXI chassis

- Large availability of vision-related and nonvision plug-in boards

Industrial PCs and Desktops

Figure 8. Radar Diagram for PC Systems

Features

- Large availability of vision-related and nonvision plug-in boards

- Time spent qualifying PCs for compatibility with plug-in boards

- Shorter shelf-life availability than validated systems from NI (Embedded Vision System, PXI)

- No need for plug-in boards if using integrated USB 2.0, USB3, IEEE 1394, [Gigabit] Ethernet ports

(although plug-in boards offer I/O and offloading) - Unlimited options for processors, memory, storage, and so on

CompactRIO and NI Single-Board RIO

Figure 9. Radar Diagram for CompactRIO and NI Single-Board RIO Systems

Features

- Modular I/O (mix and match based on application)

- Temperature rated for -40 to +70 °C

- NI Single-Board RIO is a board-only version suitable for OEM/embedded devices

- Lower acquisition bandwidth and high image decompression load on processor

(currently suitable for acquiring jpeg formats using IP cameras)

Camera Support and Camera Choice

When it comes to choosing a vision system, camera compatibility can often be the final deciding factor. The possibilities vary greatly depending on which imaging standard you choose and which type of imaging sensor is necessary for the given application. With the vast selection of cameras on the market and the great number of standards supported by National Instruments, you may need help selecting your vision system. Tables 3 and 4 provide some insight into which hardware solutions should be considered along with the different types of cameras.

Figure 10. Vision systems from National Instruments are compatible with cameras from many vendors.

| Smart Camera | Compact Vision System | Embedded Vision System | PXI and PXI Express Systems | Industrial and Desktop PCs | CompactRIO/ NI Single-Board RIO | |

| Parallel Digital | — | — | — | • | • | — |

| Camera Link | — | — | • | • | • | — |

| GigE Vision | — | — | • | • | • | — |

| IEEE 1394 | — | • | • | • | • | — |

| USB 2.0 (DirectShow) | — | — | • | • | • | — |

| IP | — | — | — | • | • | • |

| Integrated Image Sensor | • | — | — | — | — | — |

1Low-bandwidth only through non-NI analog module

Table 4. System Support for Imaging Standards

| Smart Camera | Compact Vision System | Embedded Vision System | PXI and PXI Express Systems | Industrial and Desktop PCs | CompactRIO/ NI Single-Board RIO | |

| Area scan (2D) | • | • | • | • | • | • |

| Suitability for line scan | — | —1 | • | • | • | —1 |

| Color imaging | — | • | • | • | • | • |

| Infrared | — | • | • | • | • | —1 |

| 3D laser profiling sensors2 | — | — | • | • | • | — |

| UV imaging | — | • | • | • | • | — |

| X-ray imaging | — | — | —1 | • | • | —1 |

1There are limited options available that make these sensor-system combinations possible if the hardware platform is a requirement.

23D measurements can also be implemented using multiple cameras and/or structured light sources along with triangulation algorithms.

Table 5. Suitability of Systems for Different Sensor Types