Manufacturing high-quality safety products, Ei Electronics implements test standardization across manufacturing and experience accelerated growth despite rapidly evolving conditions.

Manufacturing high-quality safety products, Ei Electronics implements test standardization across manufacturing and experience accelerated growth despite rapidly evolving conditions.

Trusted solutions that emphasize automation and analysis can create a reliable framework for component design. Trends such as miniaturization, AI, and AR/VR are driving constant adaptation, marking an era of innovation and connectivity.

Customer Stories

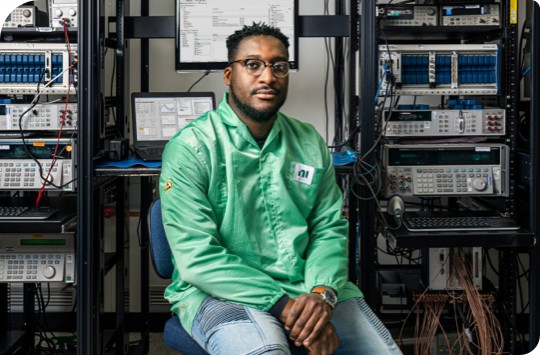

Putting our customers’ needs first and elevating the impact of their creativity and innovation is at the heart of how NI works. We’re proud to partner with the engineers and enterprises solving some of the world’s most complex challenges.

The NI platform (especially LabVIEW and TestStand) has greatly increased our productivity and is a department standard. It probably saves us at least 40 hours on each project.

Benchmark Electronics

NI Services

Maximize productivity and reduce costs with NI services. As your trusted partner and expert connector, we’re here to help you Engineer Ambitiously™.