Discover how to maximize mission readiness with a system-based approach to design and test that adapts to the evolving needs of your organization.

Topics:

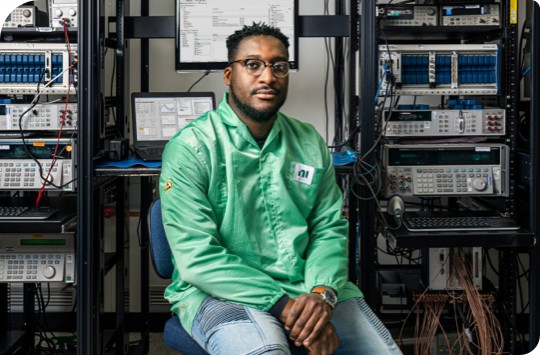

- Satellite link validation

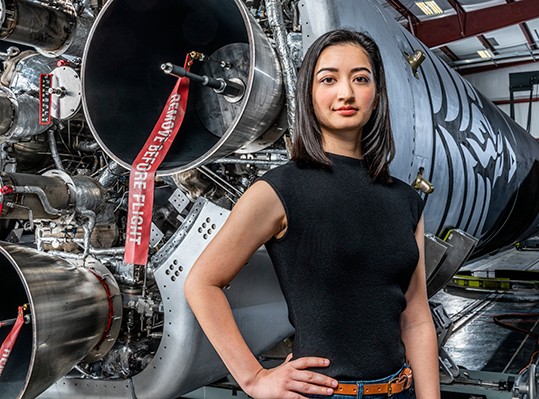

- Rocket engine test

- Embedded software validation/HIL

- Structural test

- Radar system design and validation