Maximize productivity and reduce costs with NI services. As your trusted partner and expert connector, we’re here to help you Engineer Ambitiously™.

As our world becomes more interconnected, real-time condition monitoring can help keep up with a changing product. A flexible and predictive software system can significantly lower downtime to make sure the factory line keeps up with demand.

Customer Stories

NI and NI Partners can consult, deliver, and service products from the design stage through their lifecycle. Supporting performance by implementing a strategy of efficiency and innovation creates trust in the engineered approach.

Just as we had to drive standardization in our measurement systems, we now have to do the same with our test data infrastructure.

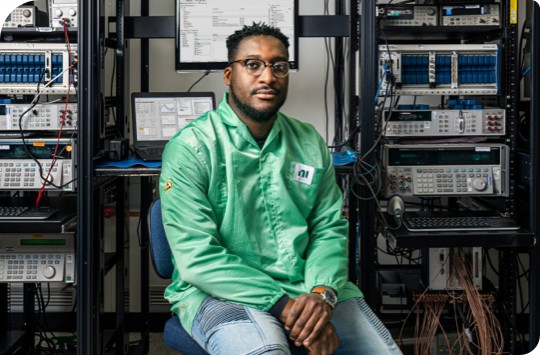

IRS, an NI Partner

NI Services

Maximize productivity and reduce costs with NI services. As your trusted partner and expert connector, we’re here to help you Engineer Ambitiously™.

An NI Partner is a business entity independent from NI and has no agency, partnership, or joint-venture relationship with NI.