Test Standardization is the Catalyst for Success

As products become more complex and time-to-market expectations shorter, test data is essential. But without standardization, you only get some of the benefits.

Increased product complexity, merging of technologies like battery and wireless into devices, and diversification of global supply chains drive both a technical and business need for improvements in production test.

Best-in-class production test teams don’t just build test stations—they execute against a test strategy that actively supports their company’s performance. Without this, teams can be seen as “just a cost center,” which limits investment. Despite ever-growing coverage requirements, tightening NPI schedules, limiting budgets, and functional globalization, teams are achieving success by using standardized processes, systems, and data to improve development productivity, test station design quality, and operational efficiency.

Standardization is a priority for production test teams seeking quality and efficiency gains. Our open, modular solutions are standardized across thousands of factories worldwide—giving confidence to engineers, business leaders, and operators alike.

Test Coverage Increase

Quicker Development Time

Less Time on Maintenance

Manufacturing high-quality safety products, Ei Electronics implements test standardization across manufacturing and experiences accelerated growth despite a rapidly evolving, smart product.

Learn how to build test systems—including test strategies, best practices, and design tradeoffs—from start to finish. This guide covers topics from modeling total cost of ownership to in-depth technical concepts such as software abstraction layers and thermal profiling.

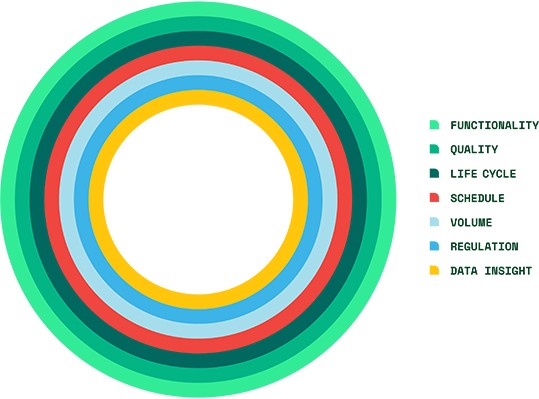

Are you struggling to balance competing priorities and outcomes? Should you prioritize quality, schedule, or volume? Our short quiz will identify your test “must-have” and provide customized recommendations for processes and tools to optimize your test strategy.