Selecting a Battery for CompactDAQ Devices

Overview

The modular and compact form factor of CompactDAQ data acquisition devices is designed to provide a portable mixed-measurement DAQ system for a broad range of applications, from examining the quality of soil to testing the structural integrity of bridges to implementing in-vehicle data logging. CompactDAQ chassis and controllers work with more than 60 C Series I/O modules to stream data back to a host over USB, Ethernet, and IEEE 802.11 b/g connections or to process and store data locally using one of the CompactDAQ controllers with an integrated, onboard processor.

Though in most of your CompactDAQ applications, you probably have access to grid power, you may take on an application that requires a portable power source to power your system. The following is a guide for selecting a battery for your CompactDAQ system when power is not readily available.

Contents

- Assessing Your Application Needs

- Choosing a Battery Chemistry

- Choosing a Size

- Application-Specific Requirements

- Connectivity

- Which Battery Should I Choose?

Assessing Your Application Needs

Every CompactDAQ application is different, and so, too, are its power requirements. Before choosing a battery, it is important to ask yourself a few key questions:

Are there alternative sources of 9 VDC to 30 VDC power available?

Sometimes battery power is the only option for an application; at other times, however, batteries may supplement an alternative power source or serve as a backup. Solar panels, for example, are a common power solution for remote, outdoor applications. But the panels cannot provide a constant source of energy, so a battery can supply power when sunlight is low or absent. Most off-the-shelf solar panel solutions are prepackaged with a battery and charging circuit already. For other applications, like a factory floor, you may be able to access DC power more readily than a data cable drop. In such an application, you may not need a large capacity battery.

Is recharging an option?

You have many different battery chemistries to choose from (see Table 1); however, batteries are categorized in only two fundamental classes: single-use and rechargeable. Single-use batteries, such as the ubiquitous alkaline AA, have less upfront cost if you plan to use battery power infrequently as a backup power source. However, rechargeable batteries can be more economical in the long term if you intend to use batteries as your primary source of power.

How long does the CompactDAQ device have to run on battery power?

The single most important factor to consider is how long your application must run on batteries. This affects the type and size of battery you should use. CompactDAQ devices, depending on which model you use, can run on small- to medium-size batteries for many hours to a full day. Multiple-day or week(s)-long applications can require much larger batteries if recharging (such as with a solar panel) or periodic servicing is not an option.

Choosing a Battery Chemistry

Batteries store energy in multiple ways, and not all batteries are made the same. Some of the most popular chemistries today are alkaline-, lithium-, or nickel metal hydride (NiMH)-based. Lead acid and nickel cadmium (NiCd) are older technologies still in use today, but their weight and longevity, respectively, may not be attractive for a portable DAQ application.

Alkaline: The most common type of single-use or disposable battery is alkaline. Most commercial off-the-shelf AAA, AA, C, D, and 9 V batteries are alkaline-based. These batteries are inexpensive, store well, and can have high energy densities. However, most alkaline batteries also have relatively low voltages, typically around 1.2 V to 1.5 V. You need at least eight of these batteries to power a 9 VDC to 30 VDC input range of CompactDAQ devices. The 9 V battery is of course the exception, but these have much lower capacity.

NiMH: Perhaps the most common rechargeable chemistry for consumer products is NiMH (nickel metal hydride). Available in the same standard sizes and voltages as alkalines (AAA, AA, C, D, and so on), these batteries provide similar to slightly lower capacities. The advantage of NiMH over alkaline (in addition to reuse) is a more constant voltage level over the life of the battery. They are also inexpensive relative to other rechargeable chemistries. A potential drawback to NiMH batteries is a short shelf life. The self-discharge rate for a NiMH battery at room temperature can be on the order of 1 percent to 2 percent per day, compared with alkalines, which self-discharge about 2 percent per year. You can reduce this by storing the batteries at colder (even freezing) temperatures.

Li-Ion: Many handheld electronics, such as laptops and mobile phones, use Lithium Ion (Li-Ion) or Lithium Polymer (Li-Poly) batteries. These chemistries are popular because of their low self-discharge rates (5 percent per month) and high energy density; Li-Ion batteries are much lighter than alkaline or NiMH batteries with equivalent capacities. For wireless DAQ applications, they also have the added benefit of higher voltage levels (typically 3.6 VDC or 3.7 VDC per cell). Most Li-Ion batteries are available in the industry-standard 18650 size (similar to an AA) or as flat rectangular cells (as in a mobile phone or camera). However, because Li-Ion can become unstable if punctured or damaged, most Li-Ion batteries come prepackaged at common voltage levels, such as 11.1 VDC or 18.5 VDC, with added current regulation circuitry. Li-Ion batteries are also more expensive and typically have longer lead (shipping) times than other chemistries.

| Chemistry | Pros | Cons |

|---|---|---|

| Alkaline | Inexpensive High capacity Low self-discharge Readily available | Single-use Low voltage level (1.5 V) |

| NiMH | Rechargeable Good capacity Readily available | Low voltage level (1.2 V) High self-discharge |

| Li-Ion | Rechargeable High energy density High voltage level (3.7 V) Low self-discharge | Expensive Dangerous if damaged Availability |

Table 1. Different battery chemistries have relative pros and cons for CompactDAQ applications.

Choosing a Size

The size and weight of a battery are determined by capacity, energy density, and voltage level. The length of time your CompactDAQ application has to run continuously is directly proportional to the capacity of your battery. Battery capacity is measured in milliamp hours (mAh). For example, a 1000 mAh battery can provide 1 A of current for one hour, 500 mA for two hours, 250 mA for four hours, and so on. Energy density is a related metric that specifies the capacity per unit of mass in watt hours per kilogram (Wh/kg). A battery with a high energy density, such as Li-Ion, weighs less than a battery with a lower energy density, such as NiMH, for the same battery capacity. Battery cell voltage also has an impact on total weight and size, because eight NiMH or alkaline batteries are (roughly) equivalent in voltage to three Li-Ion batteries.

Battery Capacity Requirements

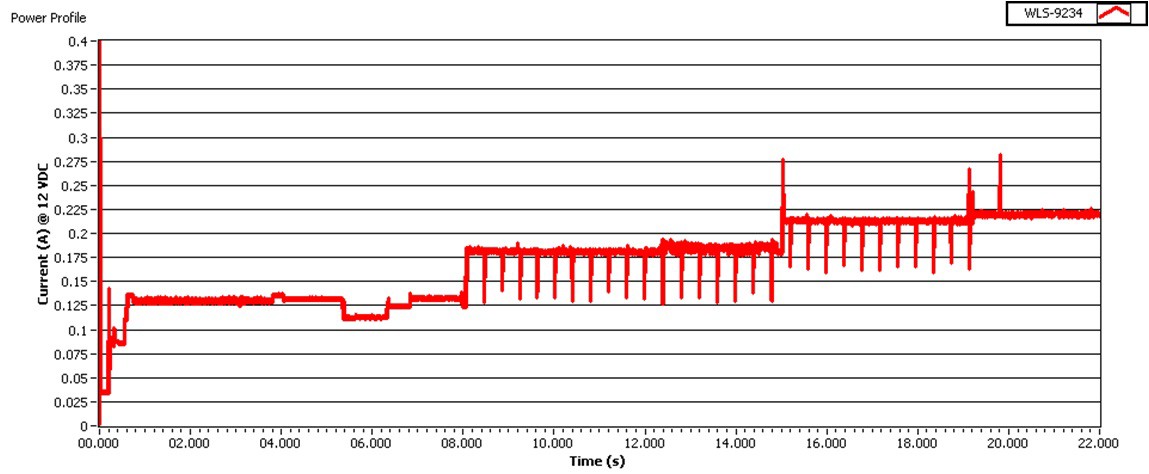

The total size of your battery solution depends greatly on the needs of your CompactDAQ application: which C Series module you are using, how long you need it to run, and which voltage level you choose. As an example, consider the cDAQ-9191 paired with the NI 9234 acquiring at the full rate on all four channels. When specifying a battery, it is important to know the peak current usage and continuous (or normal) current usage. This combination of module and chassis has a peak in-rush current of 1.67 A. Figure 1 shows the startup sequence with a steady-state current of about 220 mA after 20 seconds from a 12 VDC power supply. (These results were obtained using a PXI-4110 programmable power supply and configuring the cDAQ-9191 to authenticate with a WPA2 access point without Ethernet connected.)

Figure 1. The NI cDAQ-9191 paired with an NI 9234 boot sequence shows a power profile with a steady-state power current usage around 220 mA with a 12 VDC power supply.

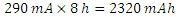

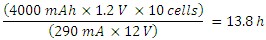

When acquiring at the full 51.4 kS/s rate on all four channels, the NI 9234 consumes an average 290 mA continuously. If you need to run this device on batteries for eight hours, you would need at least a 2320 mAh capacity battery:

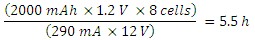

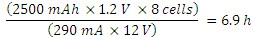

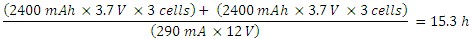

Calculating the approximate battery life of different cell chemistries is straightforward from here. First, because not all battery configurations are exactly 12 VDC, it is convenient to work with watts (W) and watt hours (Wh). Simply multiply the results above by 12 V to determine the continuous power usage for your CompactDAQ system. Then divide into the Wh capacity (mAh X nominal voltage) for your battery to determine how many hours your CompactDAQ system can operate.

Example Battery Configurations

Consider the following battery configurations for the example cDAQ-9191 paired with the NI 9234:

8x AA Alkaline Pack: Eight AA size alkaline battery cells with 2000 mAh capacity and 1.2 V average voltage connected in series.

8x AA NiMH Pack: Eight AA size NiMH battery cells with 2500 mAh capacity and 1.2 V nominal voltage connected in series.

10x 4/3 A NiMH Pack: Ten 4/3 A size NiMH battery cells with 4000 mAh capacity and 1.2 V nominal voltage connected in series.

6x 18650 Li-Ion Pack: Six 18650 size Li-Ion battery cells with 2400 mAh capacity and 3.7 V nominal voltage in a 3/2 configuration (two parallel sets of three cells in series).

Application-Specific Requirements

In the example above, it considers only one of the CompactDAQ chassis (cDAQ-9191) with one specific C Series I/O module (NI 9234) included in the system to determine which battery configuration would work for that application. However, the power consumption of the system can be drastically different from a similar application, as seen above, and an application using an 8-slot CompactDAQ controller with eight C Series modules in it. So when selecting which battery to use for your application, you should do a little work to determine the power consumption you need with your specific setup. One of the best ways you can pinpoint the system’s power consumption is to measure the current and voltage at the power connector and calculate the consumption the specific system takes. This helps you determine the battery size you need for your specific application. This is critical since the system’s power consumption completely depends on the individual components that make up that system. For more information, refer to the CompactDAQ chassis and controller specifications manuals. These feature a power requirements section with factors to consider when choosing a battery and a maximum power consumption specification that gives you the worst-case power consumption your system could potentially draw even if that draw is temporary. This section also can help you estimate the size of battery you may need for your system.

Additional considerations when determining your system’s battery size are the other system components such as the C Series I/O modules in the chassis or controller. Some C Series I/O modules require external power to be wired into the front of the module separate from the system power. Refer to the individual C Series I/O module specifications for information on the voltage input and the amount of power the module can pull.

Connectivity

After deciding on a battery pack chemistry and configuration, wiring the batteries to a CompactDAQ chassis or controller is easy. Use the NI 9976 (part number 196739-01) two-position screw terminal accessory kit or the NI 9981 (part number 783529-01) four-position screw terminal accessory kit to connect power to your CompactDAQ system. You may need to splice the leads off to a different connector for recharging as well.

Which Battery Should I Choose?

No one battery pack can solve every remote or portable power CompactDAQ application. With some planning, however, you can choose a custom battery solution for your specific CompactDAQ application.