Real-Time System Integration (RTSI) and Configuration Explained

Overview

Introduction

RTSI stands for Real-Time System Integration. It is a bus found on many National Instruments devices that, when cabled together with a RTSI cable, is used to share and exchange timing and control signals between multiple boards. It is usually used for synchronization purposes.

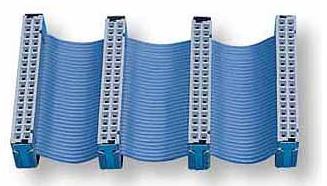

A RTSI cable is shown below:

The NI-DAQmx driver does routing and driving of the RTSI lines automatically. The DAQmx Export Signal.vi allows you to explicitly route signals to the RTSI bus. In LabWindows/CVI or other text based languages, use the DAQmxExportSignal function. In a .NET environment, use the ExportHardwareSignal method.

For more information on the DAQmxExportSignal function or the ExportHardwareSignal method, go to Start Menu»All Programs»National Instruments»NI-DAQmx»NI DAQmx Documentation and open the NI-DAQmx C Reference or NI-DAQmx .NET Help.

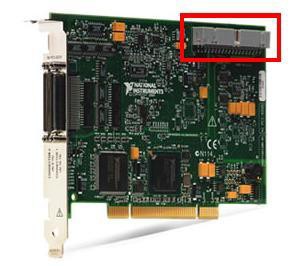

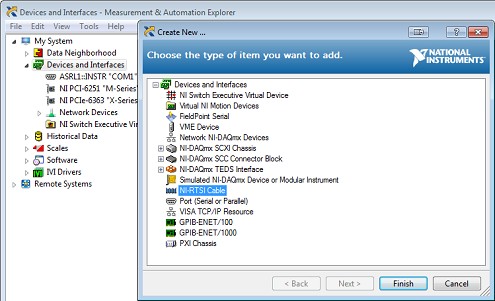

After physically connecting the RTSI cable to the RTSI connector on the devices, the cable must be registered in Measurement & Automation Explorer (NI MAX). To create a RTSI cable, right click on Devices and interfaces, click Create New, in the new window select NI-RTSI Cable as shown in the screenshot below and finally click on Finish.

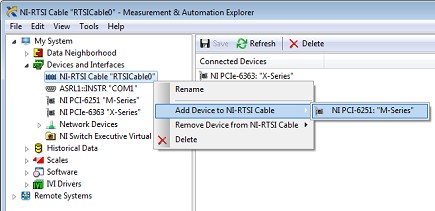

Then add devices to the RTSI cable by right clicking on the NI-RTSI Cable and associating each card which is physically connected with the cable as shown in the screenshot below.

At this point, if any synchronization method is used among the cards or if both are simply used on a single task, the NI-DAQmx driver will automatically route all the required signals through the RTSI bus to make sure the devices are synchronized.