Maximize productivity and reduce costs with NI services. As your trusted partner and expert connector, we’re here to help you Engineer Ambitiously™.

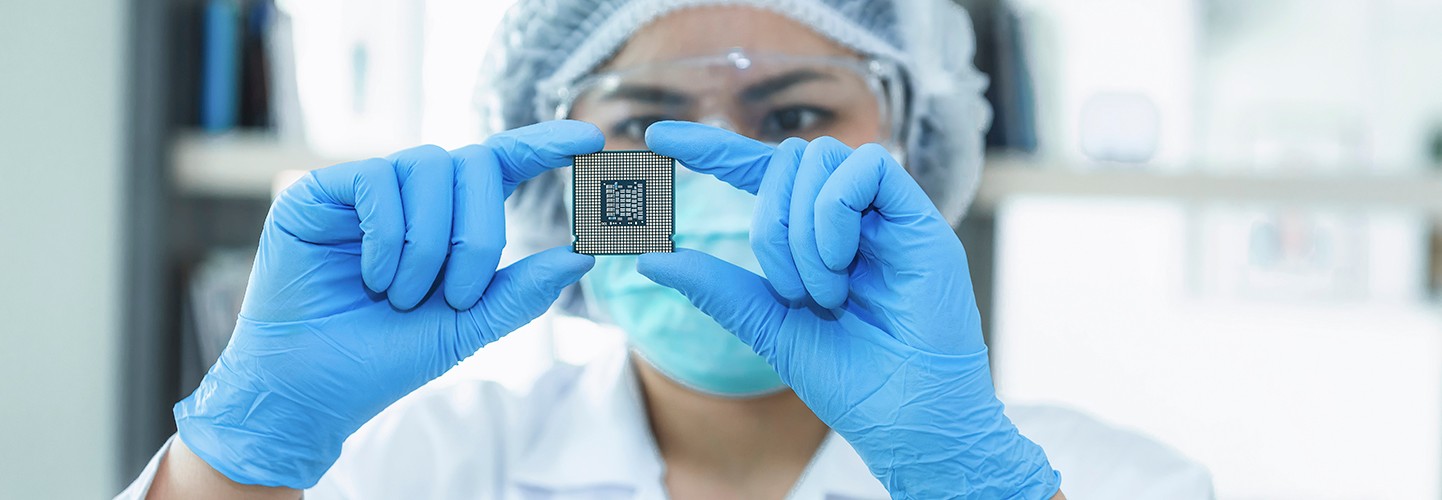

If you’re anything like us, you’re probably wondering: What’s next for semiconductor? From 5G to optical sensing to autonomous driving, your industry plays a major role in shaping a better future. It's our privilege to innovate with you.

Customer Stories

Putting our customers’ needs first and elevating the impact of their creativity and innovation is at the heart of how NI works. We’re proud to work with the semiconductor engineers and enterprises solving some of the world’s most complex challenges.

NI Services

Maximize productivity and reduce costs with NI services. As your trusted partner and expert connector, we’re here to help you Engineer Ambitiously™.